The production platform

for your individual grinding solution.

Basic Data

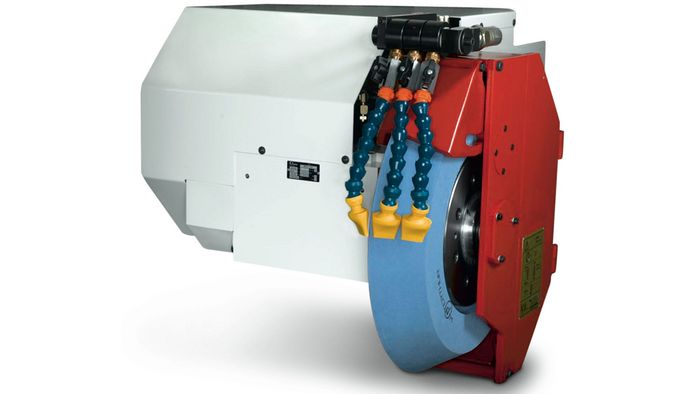

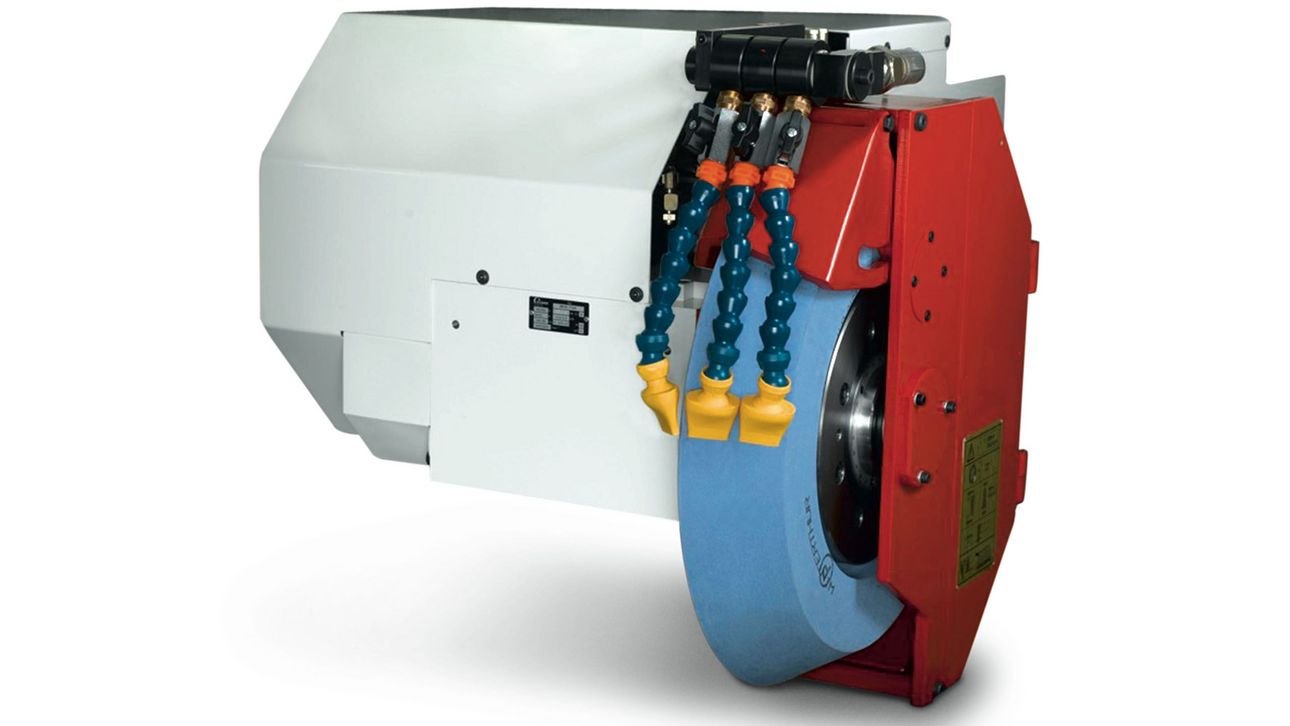

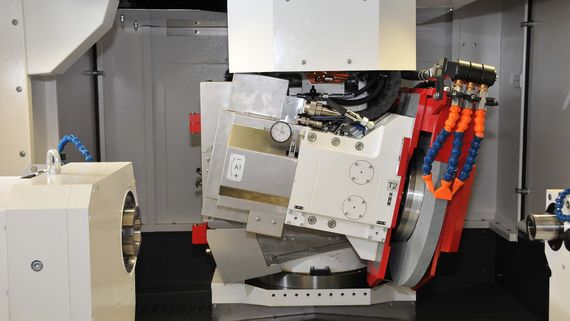

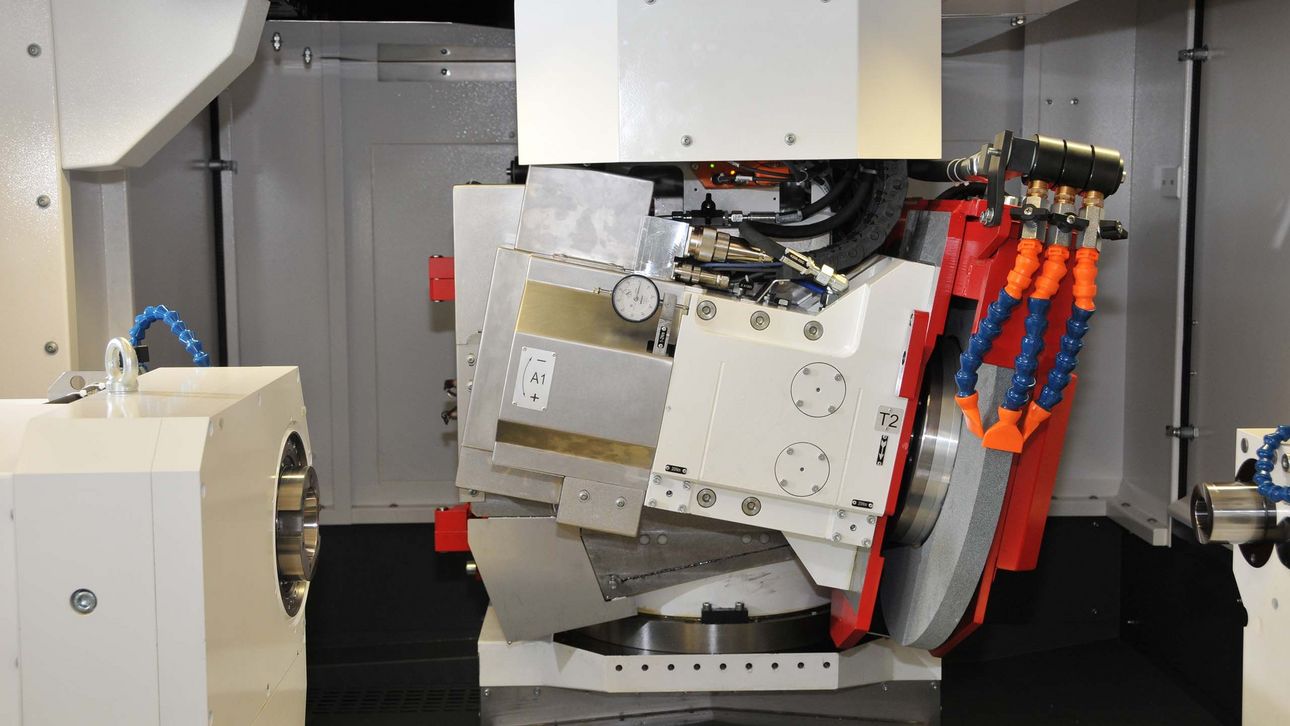

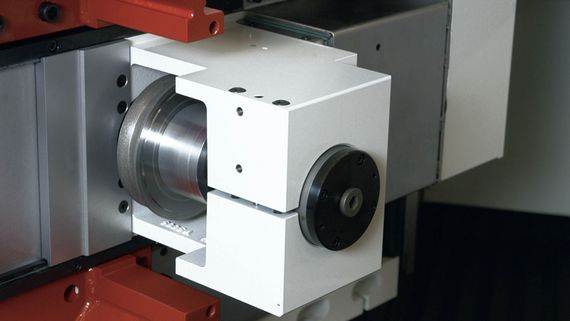

The S22 is a production platform for the mass production of medium-sized workpieces. It has distances between centres of 800 mm (31.5") and centre heights of 175mm (6.9") / 225mm (8.8"). It can machine workpieces with a maximum weight of 150kg (330lbs).

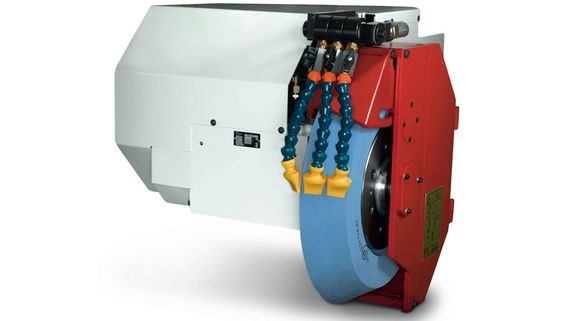

The S22 with its extensive expansion options can be configured for every grinding application to be the perfect production machine. Highly dynamic axis drives, high-quality STUDER guideway systems, short reaction times and optimized traverses form the basis of the S22. The high-speed grinding option (HSG) contributes to increasing productivity with its peripheral speed of up to 140m/s (27,600 sfpm).

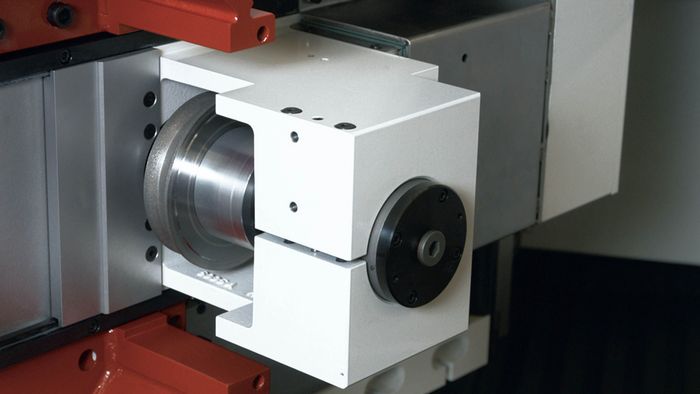

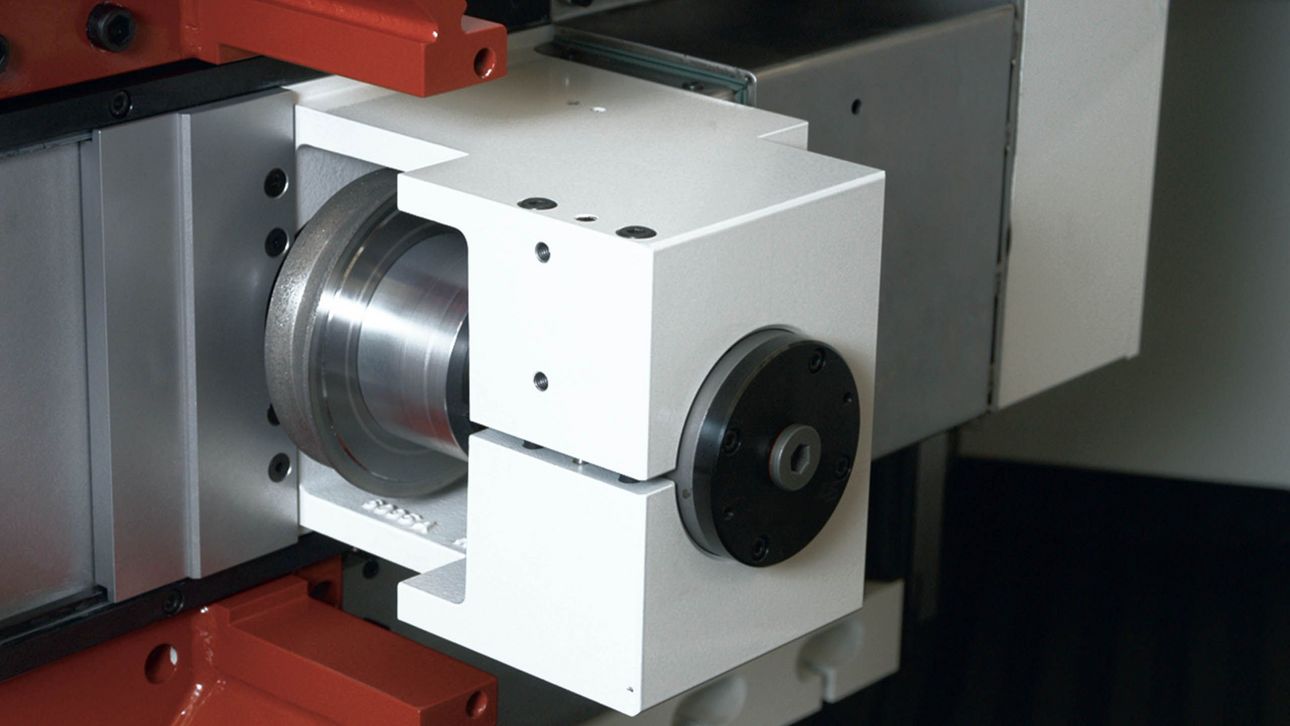

Images

Hardware / Software

Hardware:

- Granitan® S103 mineral casting machine base

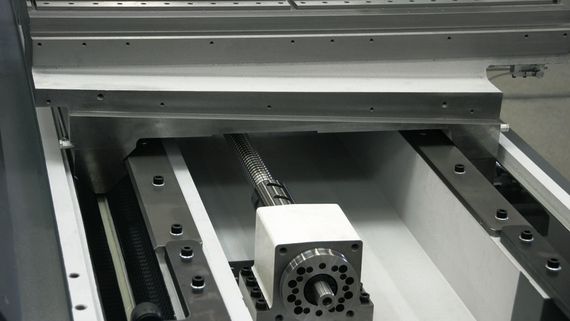

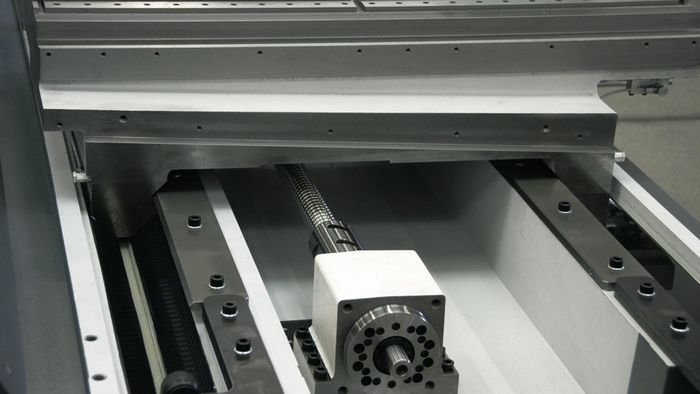

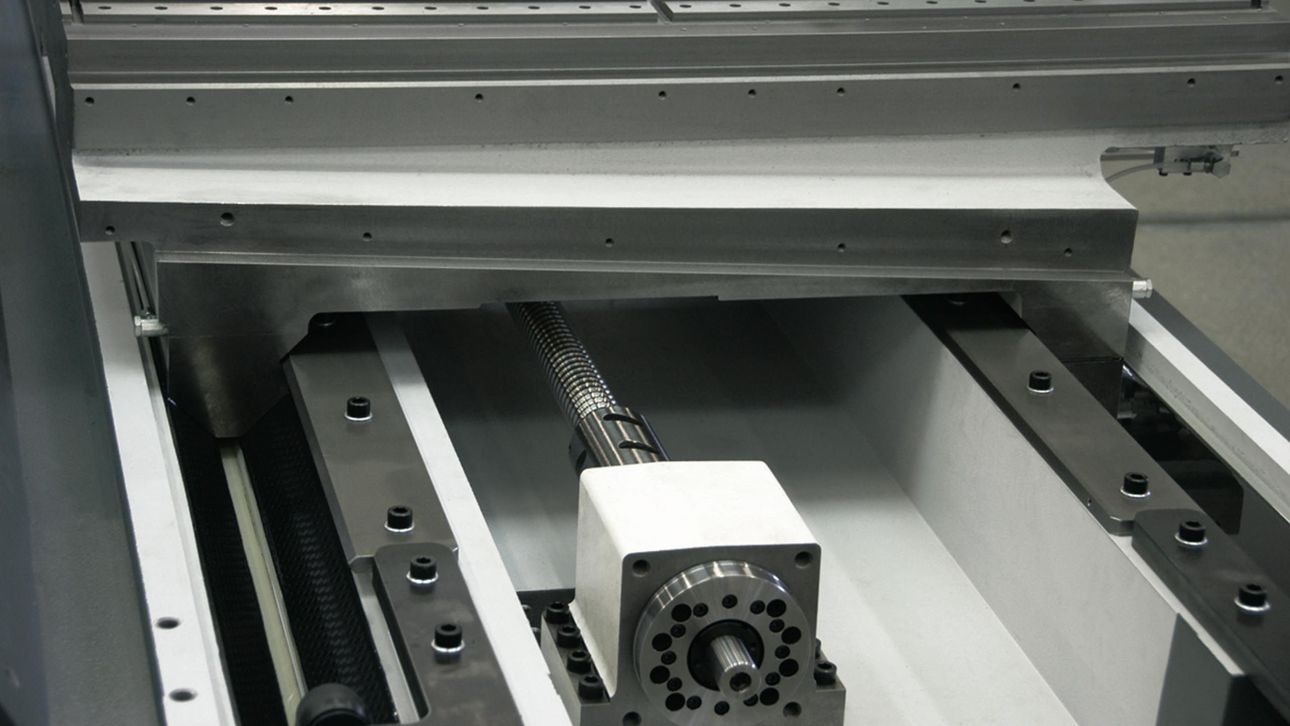

- Cross slide X: anti-friction guideways with ball-screw

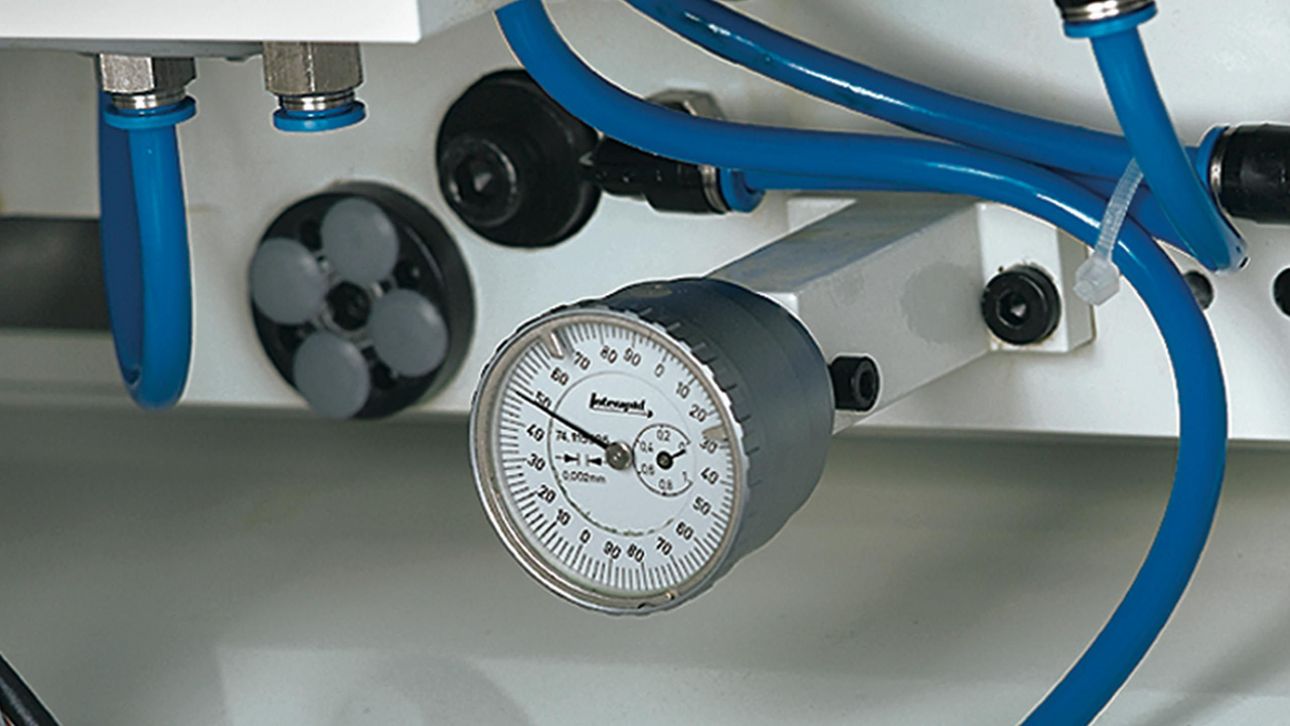

- Longitudinal slide Z: guideway with patented surface structure and ball-screw drive

- C-axis for the workhead

- Application-specific workhead concepts

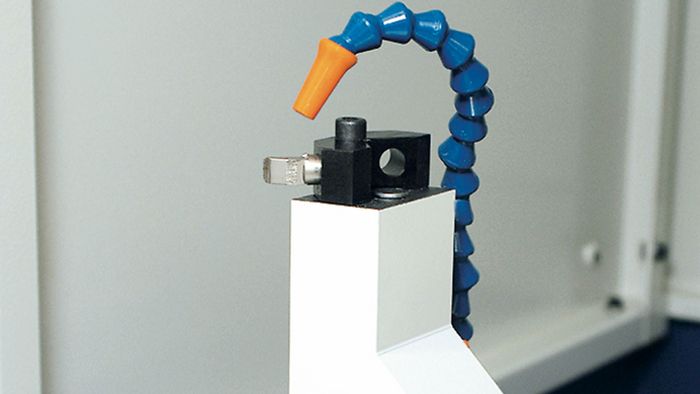

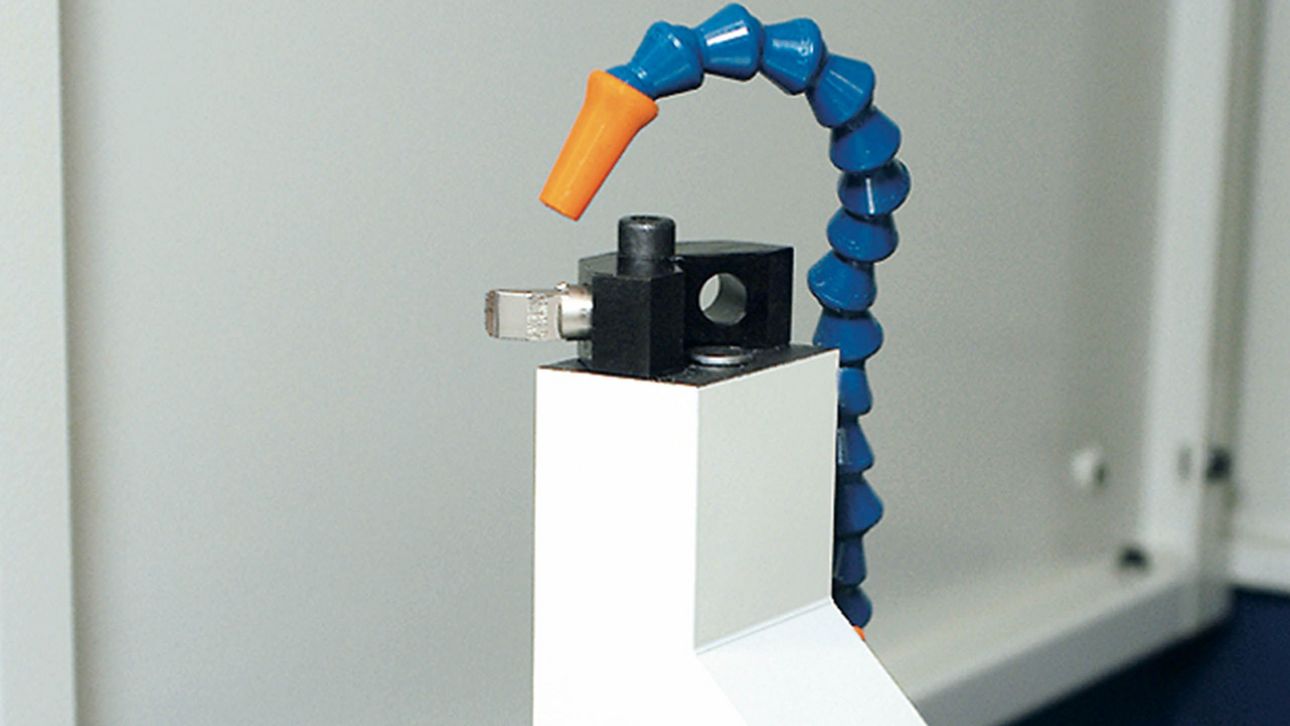

- Additional NC axis for profiling the grinding wheel

- Full enclosure with movable front panels for optimal accessibility

- Integrated loading unit or loading cell for loading and unloading from left, right or above

- Large range of accessories

Software:

- Easy programming with StuderWIN on Fanuc 31i-A

- StuderGRIND programming software to create grinding and

dressing programs - Standardized interfaces for loader and peripheral devices

Technical Data

Linear Axes

Max. Travel X

310 mm

Max. Travel Speed X

15'000 mm/min

Max. Travel Y

100 mm

Max. Travel Z

850 mm

Max. Travel Speed Z

30'000 mm/min

Spindle drive

Max. Spindle Power

15 kW

Max. Number Of Revolutions

3'200 /min

Max. Grinding Wheel Diameter

610 mm

Max. Grinding Wheel Width

160 mm

Swiveling Axes

Swiveling Range A

26 °

Swiveling Range B

195 °

Swiveling Range C

∞ °

Workpiece Data

Workpiece Length

700 mm

Workpiece Diameter

449 mm

Max. Workpiece Weight

150 kg

Distance Between Centers

800 mm

Center Height

225 mm

Downloads