Precision – accurate results

for every workpiece

Basic Data

It combines maximum precision with flexible application and, with modern technology and worldwide service, ensures your productivity for the future.

- Repeatability – consistent quality throughout the entire service life

- Precision – accurate results for every workpiece

- Versatility – flexible software and intuitive operation

- High availability – robust construction and worldwide service, including digital

- Strong partnership – UNITED MACHINING SOLUTIONS (grinding, milling, EDM)

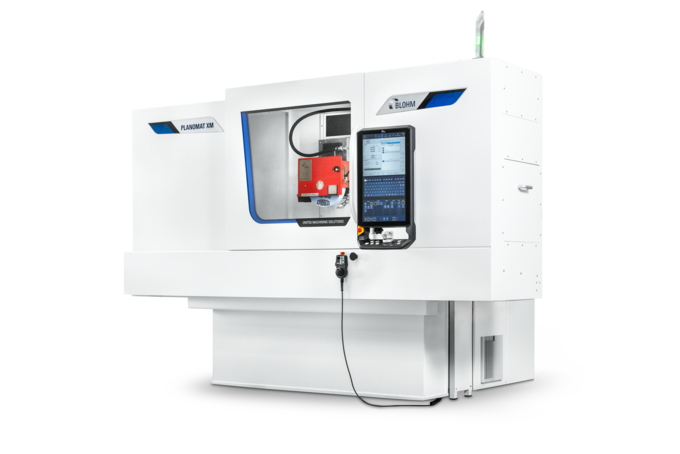

The PLANOMAT XM 408 is the solution for demanding machining tasks – from complex shapes to high-precision parts in a wide variety of materials.

Whether deep grinding or multi-stage production in a single setup: with its flexibility and efficiency, it sets standards in surface and profile grinding. A powerful drive and state-of-the-art control technology guarantee maximum precision and reliability. Our application engineers work with you to develop customized solutions for your individual requirements.

Hardware

- Modular machine concept

- Design characteristics: very high rigidity, minimum vibrations, minimum

- thermal influences

- Precision linear guideways

- High quality, recirculating ball screws

- Spindle power: 8 kW

- C.O.R.E. panel

Software

- Pre-programmed grinding and dressing cycles

- Intuitive operation

- C.O.R.E. OS operating system

- Digital Solutions

Technical Data

Linear Axes

Max. Travel X

900 mm

Max. Travel Speed X

30000 mm/min

Max. Travel Y

500 mm

Max. Travel Speed Y

3750 mm/min

Max. Travel Z

360 mm

Max. Travel Speed Z

3750 mm/min

Spindle drive

Max. Spindle Power

8 kW

Max. Number Of Revolutions

6000 /min

Max. Grinding Wheel Diameter

300 mm

Max. Grinding Wheel Width

50 mm

Workpiece Data

Max. Workpiece Weight

1500 kg

Table Sizes

800 x 400 mm