STUDER Looks Back on a Successful EMO 2025: Innovative Grinding Technology Impresses Trade Visitors

The world premiere of the S23 and groundbreaking grinding technology underscore the innovative strength of the Swiss cylindrical grinding specialist in ensuring the competitiveness of its customers.

Fritz Studer AG looks back on a successful EMO 2025 in Hanover. We are delighted that our innovations in grinding technology have met with such great interest among international trade visitors," said CEO Sandro Bottazzo. The Swiss quality manufacturer of cylindrical grinding machines presented numerous innovations at the world's leading trade show for manufacturing technology from September 22 to 26.

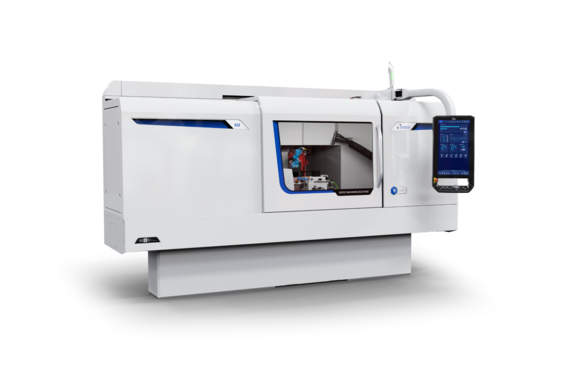

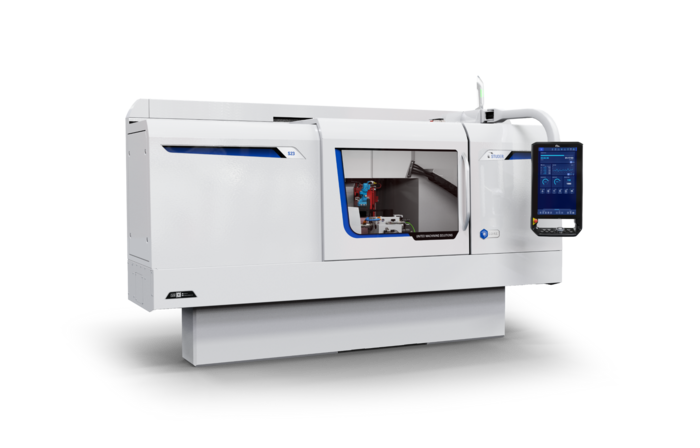

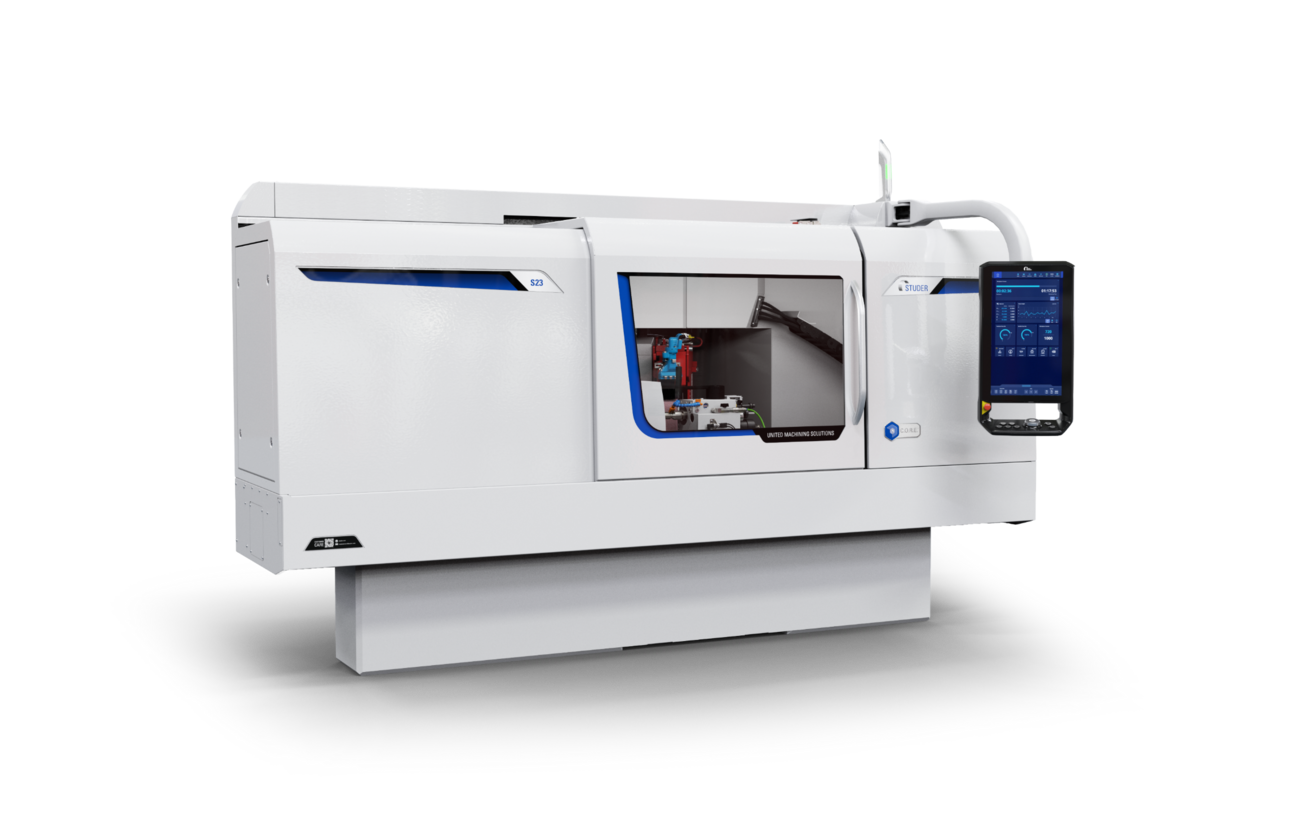

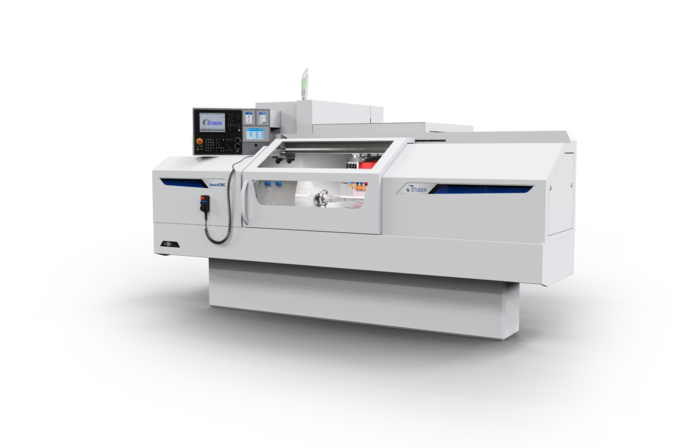

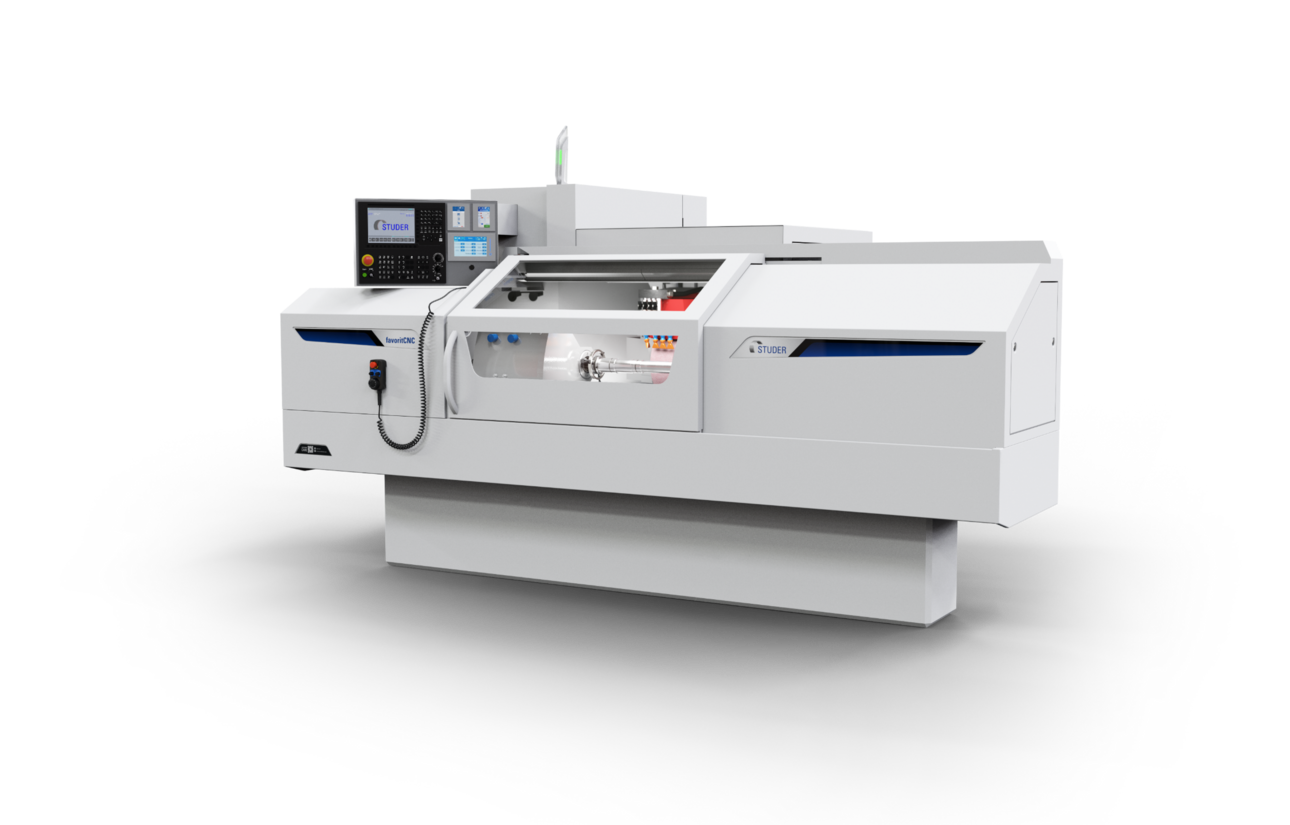

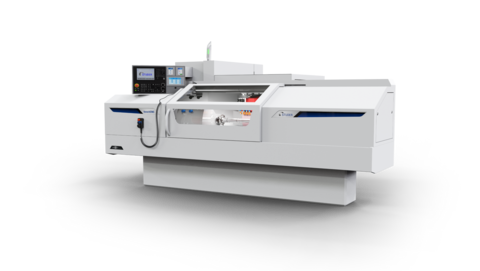

World Premiere of the S23 and new Generation of favoritCNC

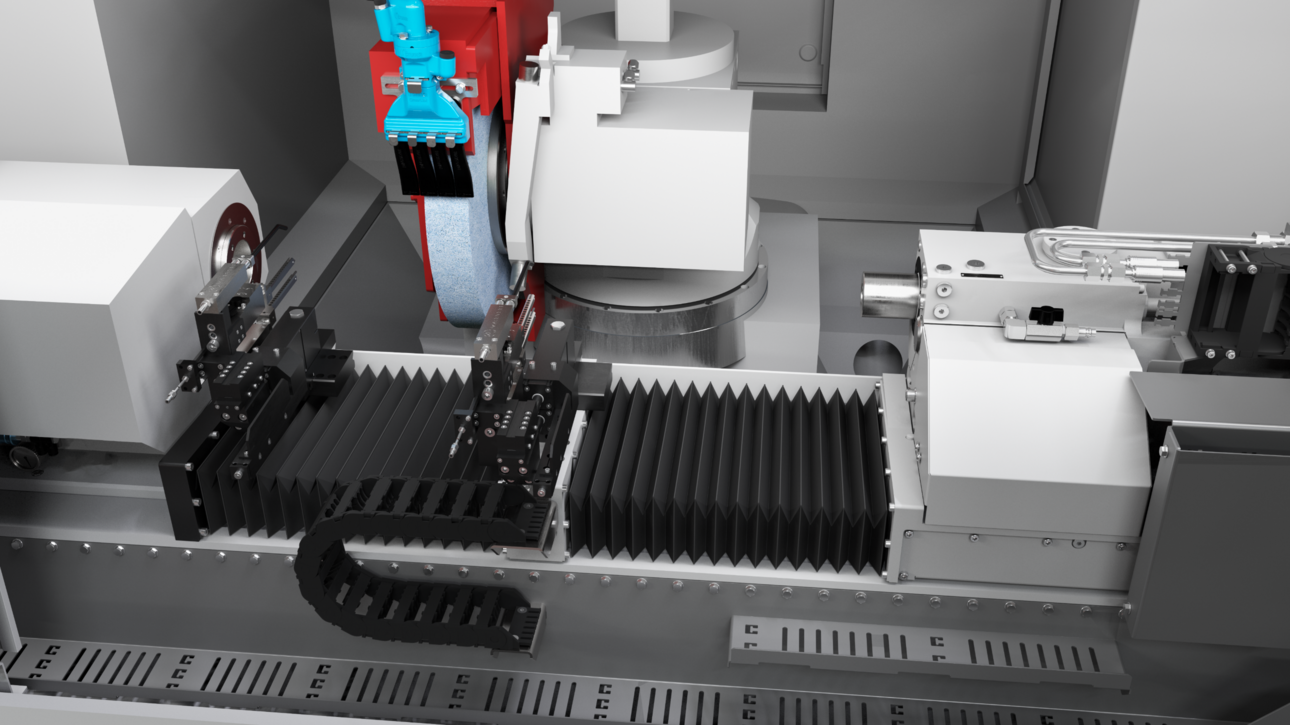

One highlight was the world premiere of the new S23 universal cylindrical grinding machine. This versatile CNC machine offers state-of-the-art grinding technology for maximum precision and reliability in a space-saving design. Thanks to its high-quality features, the S23 perfectly complements the portfolio between the entry-level and premium segments. It impresses with features such as the modern C.O.R.E. hardware and software architecture, an automatic B-axis with 1° Hirth serration for up to three grinding tools, and a Granitan machine base with excellent thermal and vibration properties.

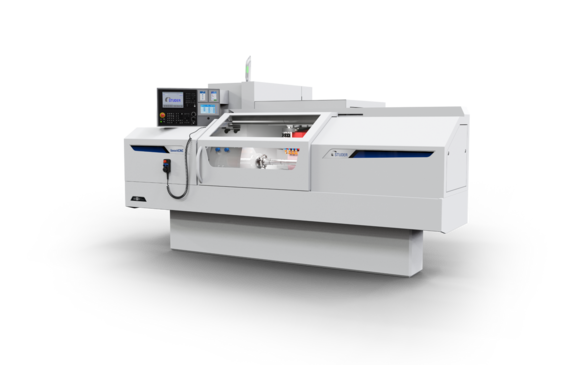

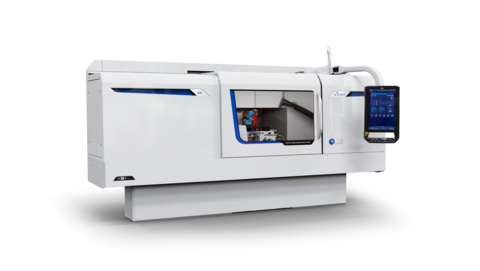

The new generation of favoritCNC, which STUDER has equipped with modern capabilities and optimizations, also attracted a great deal of attention. The popular entry-level machine now features an updated CNC control (Fanuc 0i-TFP), an automatic operating door and loader interface for automation solutions, a resource-saving belt spindle system, and a machine base with a larger X-guideway distance for even greater stability. In addition, the new Conventional Mode facilitates the transition between manual and CNC grinding.

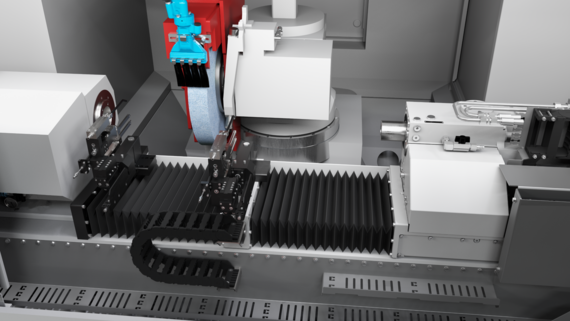

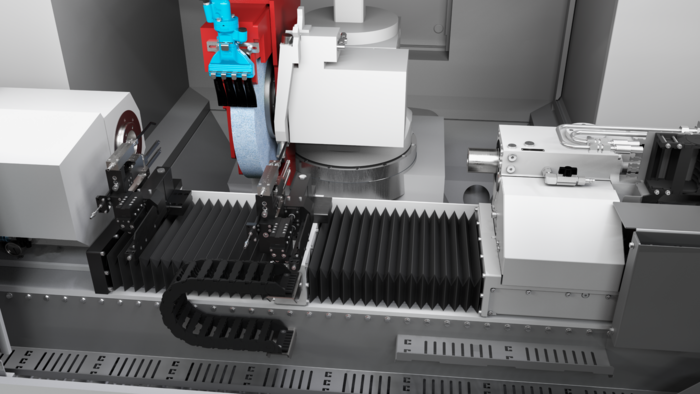

Innovative Axis System and WireDress® for Internal Cylindrical Grinding

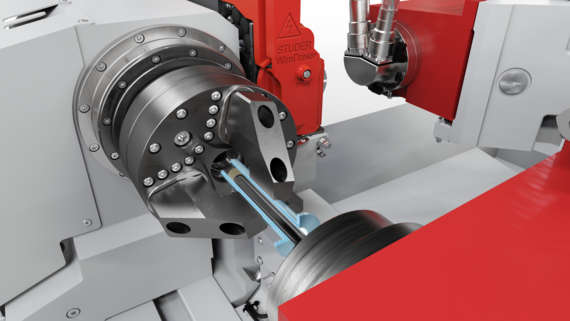

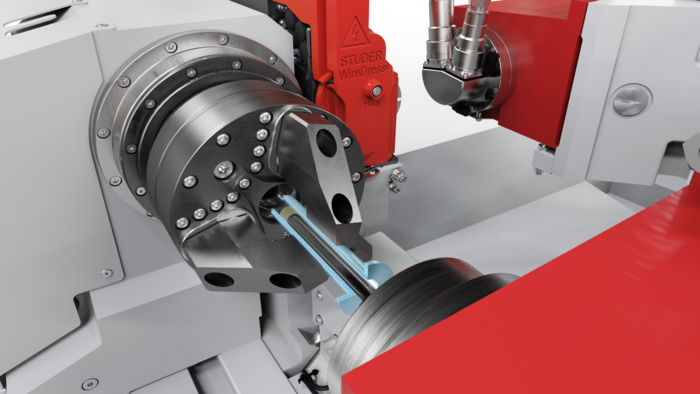

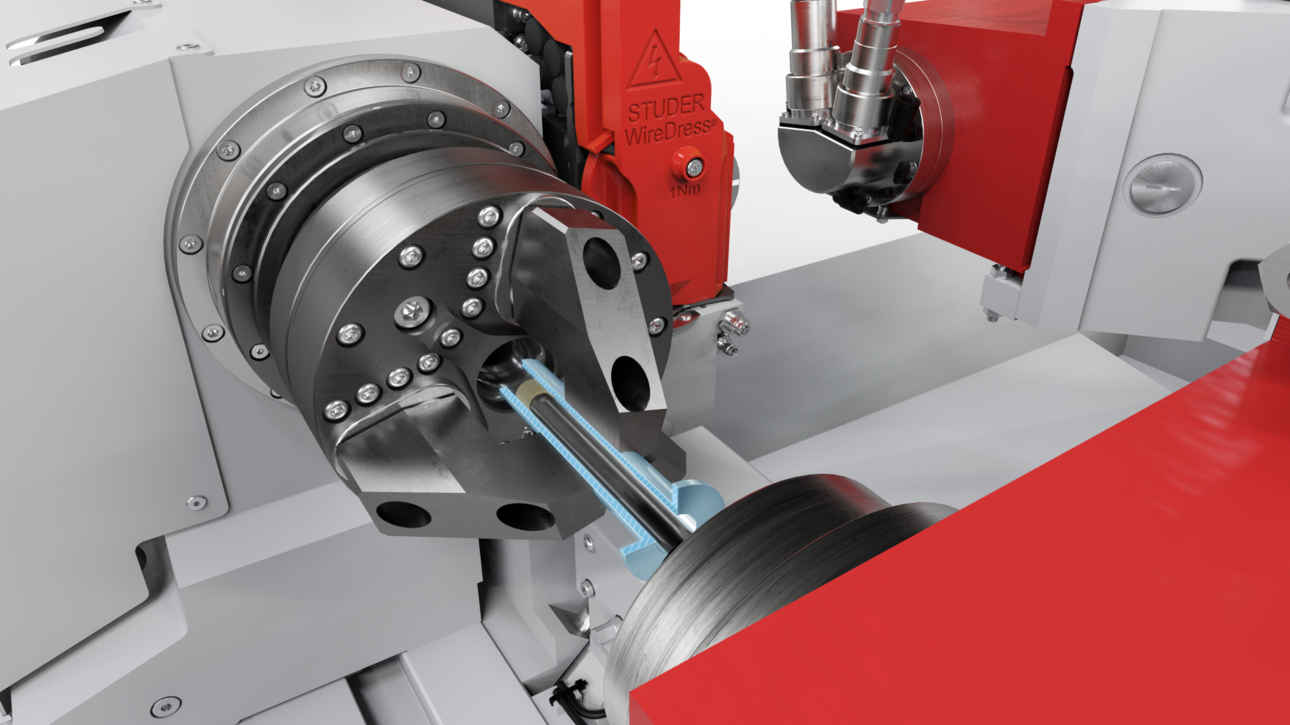

On the S31 universal cylindrical grinding machine for small to large workpieces, STUDER demonstrated an innovative axis system that sets new standards in automated precision cylindrical grinding. The long W-axis enables automatic adjustment of the tailstock position to different workpiece lengths, while the active R-axis with an in-process measuring system can scan complex geometries on the workpiece. A special feature of the system is the direct measurement of the clamping force. This ensures precise, reproducible clamping conditions for workpieces. The clamping force is also visible to the machine operator on the control screen.

Another leap forward in innovation was presented with the introduction of the WireDress® non-contact dressing system for internal cylindrical grinding. The technology, which is based on wire electrical discharge machining, opens up new geometric manufacturing possibilities with diamond and CBN grinding wheels with sintered metal bonds. This is made possible by a new internal grinding spindle that can transmit current at full grinding speed.

"At EMO 2025, STUDER was able to show how we will continue to contribute to our customers' success in the future. A clever mix of reliable and innovative grinding technology brings decisive advantages for competitiveness," summarized Pascal Schärer, Sales Manager for Central Europe.