CNC machining of medical precision parts

Precision is crucial in medical manufacturing. Instruments of the highest quality are indispensable for saving lives in the medical field. In this Motion Blog, discover how WALTER machines can optimize your production processes to meet the highest standards in medical technology.

HELITRONIC and HELICHECK: Manufacturing and measuring from a single source

The HELITRONIC MINI PLUS provides optimal solutions for processing smaller tools and small medical components. This machine is ideal for small to medium diameters (up to 20 mm/0.785") and, with the option of automation, lets you easily increase your production capacity. We recommend the HELITRONIC VISION 400 L for larger parts that require high dynamics of all linear axes. It is ideal for manufacturing complex geometries with high precision.

The HELICHECK series precisely monitors the quality of manufactured parts. Non-contact and wear-free measurement by the HELICHECK PLUS optical measuring machine guarantees the utmost precision, particularly vital for medical components.

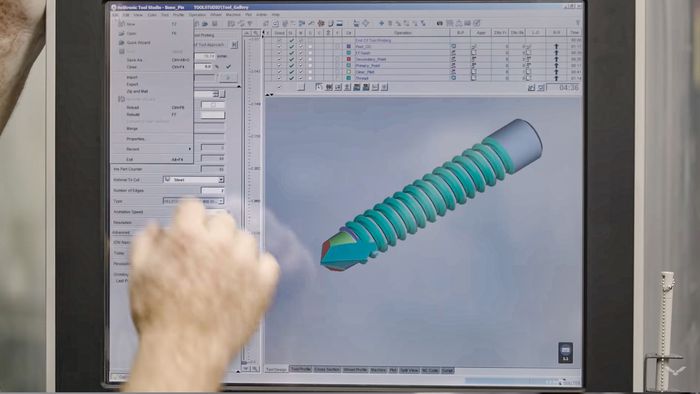

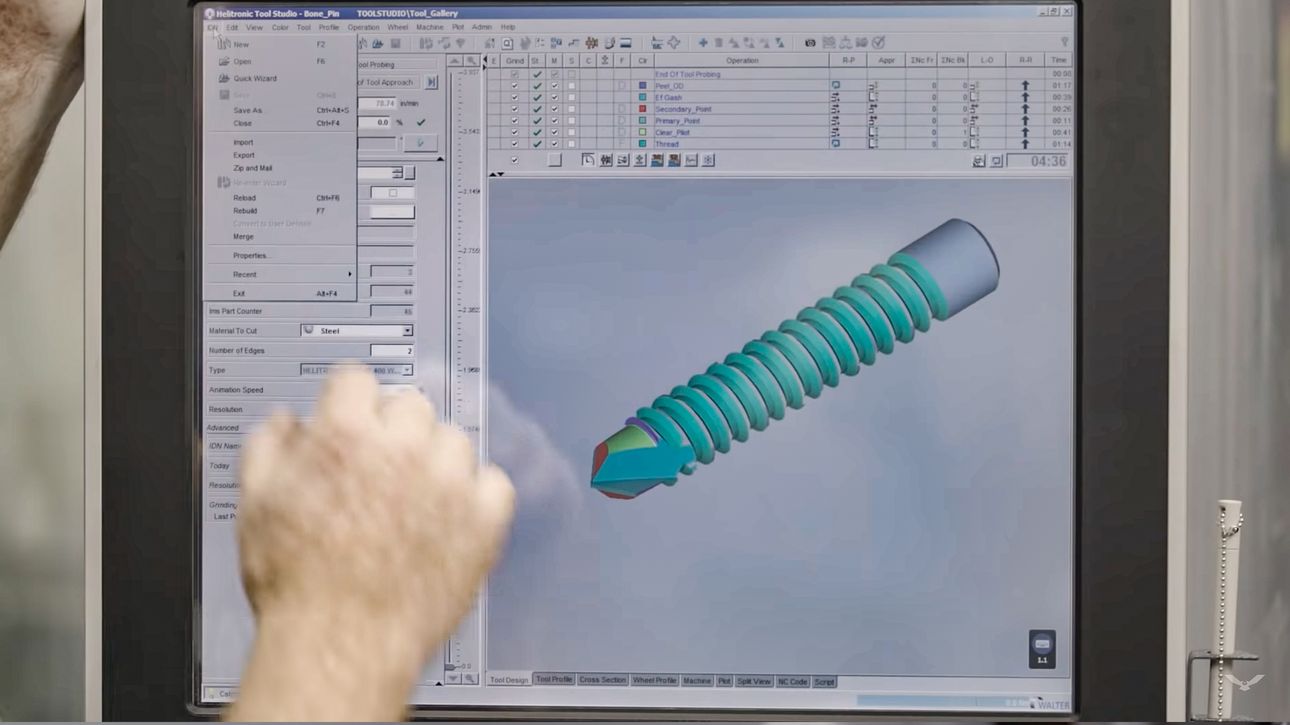

HELITRONIC TOOL STUDIO Software Efficient design and machining

WALTER software simplifies the design, programming, simulation, and production of medical tools, such as bone nails, bone screws, bone cutters, and cranial drills. Seamless integration into C.O.R.E technology allows you to produce complex tools in a single clamping.

Automation with robot loader: Increased production output

Loading time can be minimized by combining WALTER machines with a flexible 6-axis robot loader. The robot loader has a capacity of up to 7500 tools. Various devices are available for different applications, from knee prostheses to drills. The self-learning loading robot considerably simplifies the set-up process.

Want to Find out More?

Talk to us today about your application and find the perfect WALTER machine to suit your requirements.

Image credits: Grinding bone screws by TITANS of CNC