For the Benefit of the People.

Around the world, people are getting older and the demand for medical technology is therefore also growing. According to the "Global Burden of Disease" long-term study, the human life expectancy has increased worldwide from on average of 65.3 years in 1990 to 71.5 years in 2013. Those born in 1990 will spend an average of 56.9 years in good health and those born in 2013, 62.3 years – with age, the average time suffering from poor health increases proportionally. The overall growth of the world population has a secondary effect, the sales of the medical technology sector are consequently growing. While the sales in this market totaled US$ 387 billion in 2016, it is forecast to increase to US$ 522 billion by 2022.

With its three technology divisions, the UNITED GRINDING Group provides expertise for the different medical technology sectors.

Challenges for Medical Implants

Bone drills to drill holes so that plates or splints can be secured to fractured bones as well as dental drills and implants are produced using tool grinding machinery. Particularly sharp cutting edges and accurate concentricity are essential for these drills. The same applies for implants, for instance in shoulders or hips. In this process, WALTER machines such as the HELITRONIC MINI POWER or HELITRONIC MICRO are used.

In the area of surface and profile grinding, the production spectrum ranges from plastic injection tools, for example for inhalers, to nails, syringes and bone saws. "Just like all other industries, the medical technology sector always demands maximum quality and precision", BLOHM JUNG Product Manager Thomas Mank explains, continuing by saying that "our J600 and PLANOMAT machines meet additional requirements in this context, resulting from the certified machining process."

A very broad spectrum is also served by STUDER with applications for implants, tablet production and much more. "Nowadays medical technology no longer requires special machines. Machining is usually possible with standard machines", STUDER medical specialist Antonio Bottazzo explains. "This boosts flexibility and availability."

Medical technology is also responsible for the majority of orders at IRPD. "We have been working together with the state hospital for almost ten years", Raphael Schmid, Manager Reverse and Medical Engineering, says. During this time IRPD has developed a host of applications with the hospital.

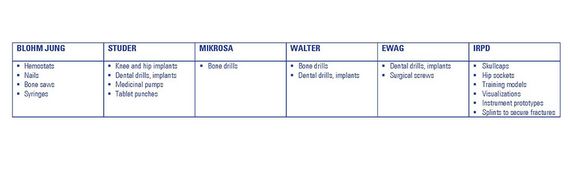

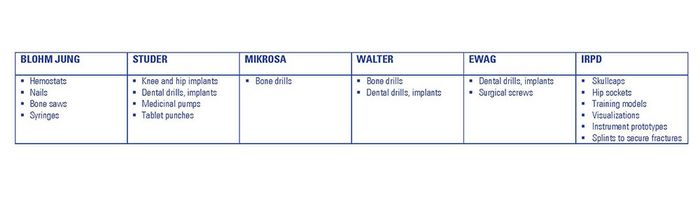

Examples of Medical Applications Within the UNITED GRINDING Group

Manufacturers of medical implants face the following challenges:

- Materials must be stronger, tougher, and more durable without becoming brittle.

- Implants must meet maximum quality standards involving certified composition and a perfect surface.

- With the growing demand for implants, rapid market introduction is becoming increasingly important.

- Expensive materials and demands for efficiency in the production of medical implants require the use of automation.

Compliance Requires Reproducible Precision

The approval procedures for the manufacturing of medical implants are stringent, as the way it should be for components that are ultimately implanted into the human body. Each production process for medical implants must be certified, including a test production run as part of which samples are inspected and checked for potential contamination, surface quality, and other technical specifications. Experience in automating grinding guarantees a reproducible, efficient process that is necessary to produce a perfect part each time.

Production processes for medical implants may vary significantly from those in the automotive and aerospace industry. However, with very few exceptions, they are similar in the demands for high-precision parts with low rejects. Precision, speed, and simple changeovers are paramount.

The automation of grinding not only helps in meeting OEE targets, but it also makes sure that a continuously high quality of the components manufactured is achieved.

Look into UNITED GRINDING solutions today to find out how we can help you improve your production process for medical implants.