The Digital Twin simulates grinding processes, saving time and money

The Digital Twin is a virtual representation of another element, e.g., a machine, a workpiece, or a process. In the Industry 4.0 environment, the Digital Twin has become a very popular concept with many benefits. Using a Digital Twin, you too could benefit from the production efficiency gains.

The aerospace industry places special demands on production: The quality requirements are extremely high, the machining processes are very complex, and the materials used are also difficult to machine. In addition, the workpieces that are processed, such as turbine blades, are costly—another reason that production errors must be avoided at all costs.

The Digital Twin has several benefits in this challenging production environment. This is why the Digital Twin is used on the MÄGERLE 5-axis grinding centers: the MFP 30,MFP 50,MFP 51, and the MFP 100.

You can read about the benefits of using the Digital Twin here:

1. Reduced start-up time

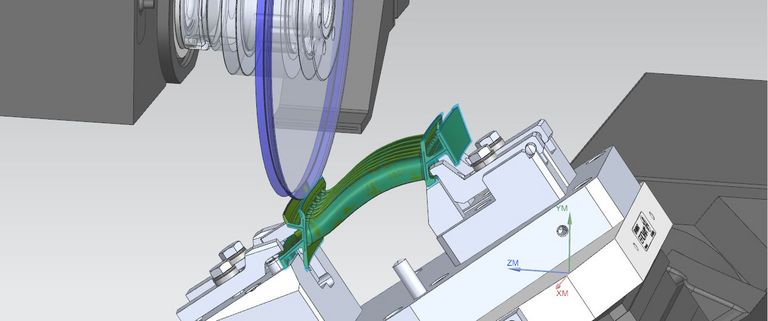

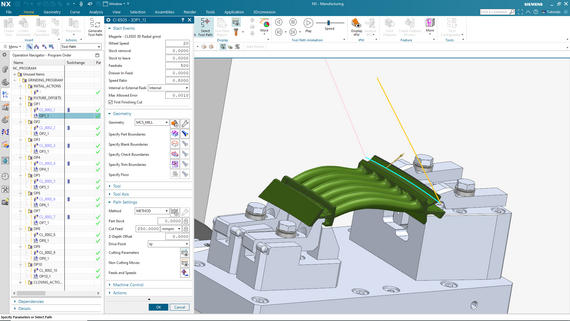

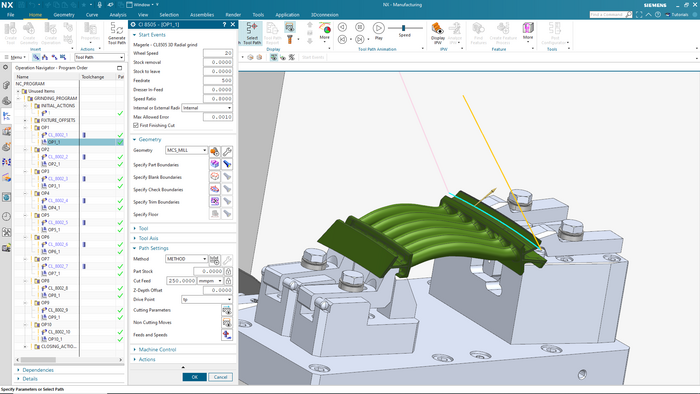

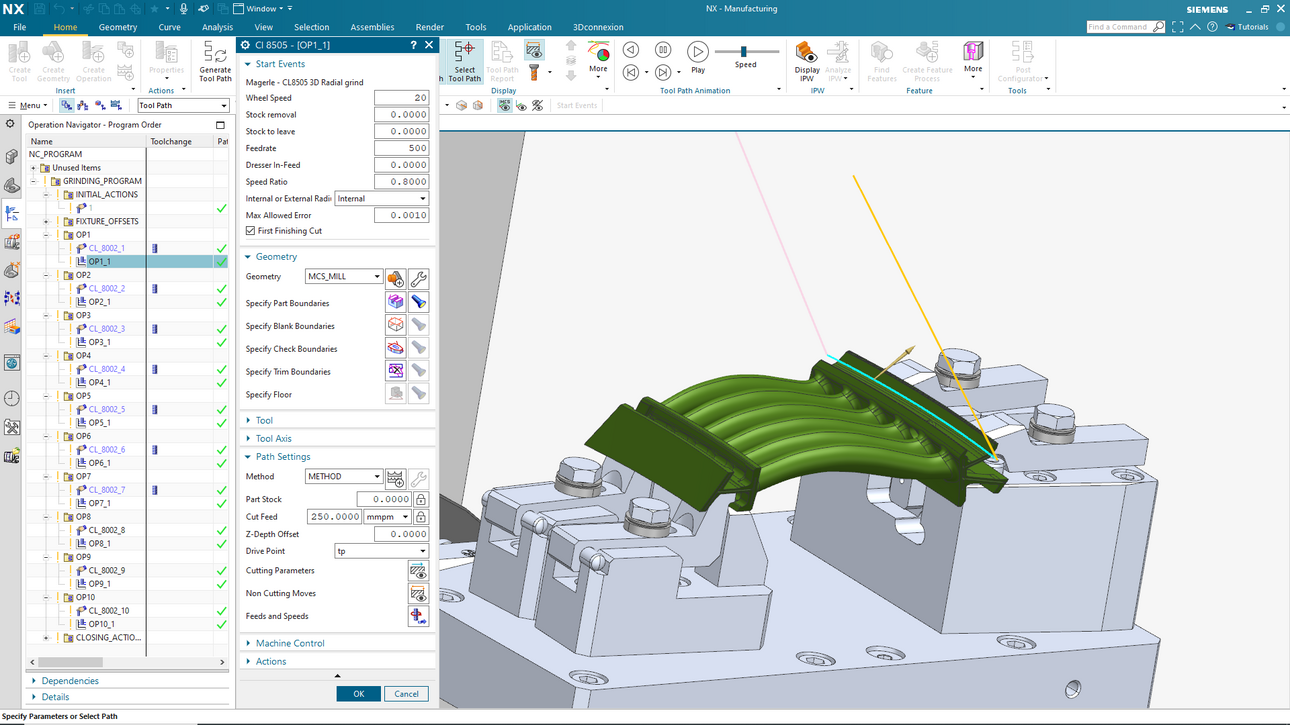

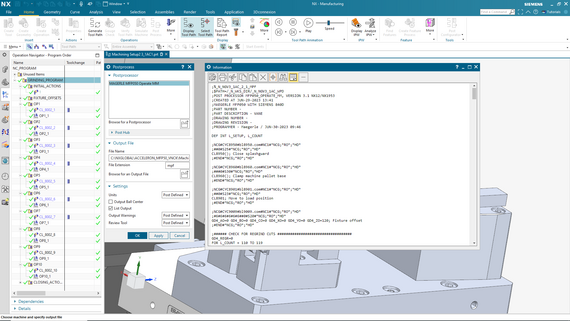

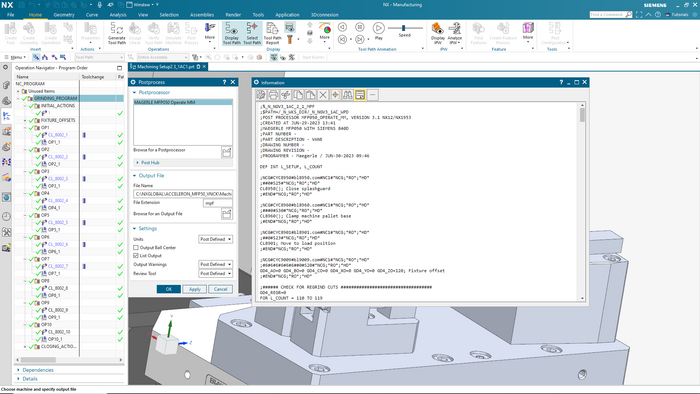

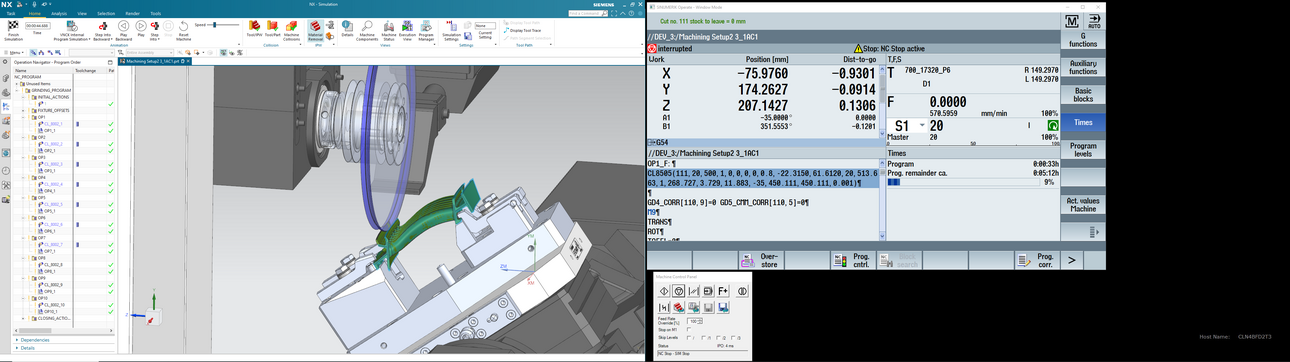

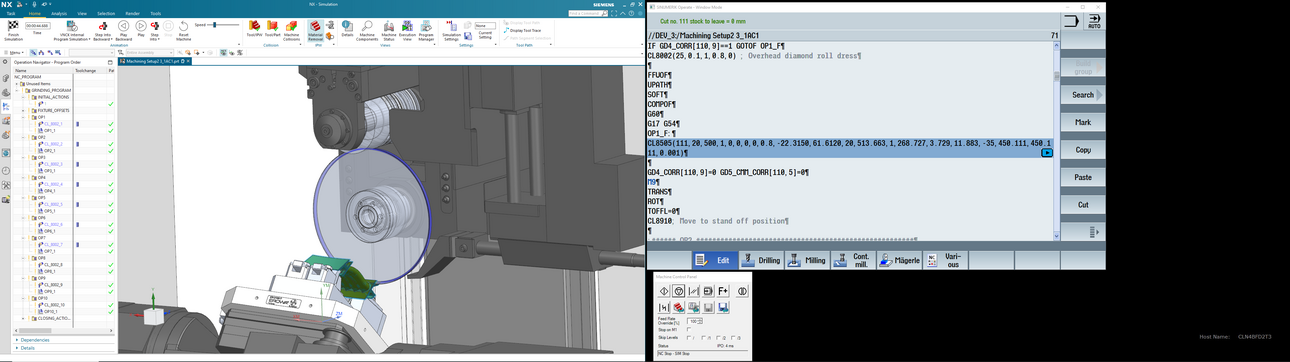

The set-up phase of a new workpiece can be very time-consuming, especially if it is a complex and multi-stage grinding process. This is the case when machining aero-engine turbine blades in the aerospace industry, where 10 or more grinding operations are often performed in one clamping. While the traditional turbine blade approach involves programming, testing, and optimizing each process step on the machine, the Digital Twin makes this all virtual. The entire grinding process can be simulated one-to-one on a computer, optimizing the process considerably more effectively. This efficiency can translate into a time saving of up to 75%, which in specific cases equates to several working days. In a specific example, the use of a Digital Twin reduced the set-up phase of turbine blades from seven days down to one day.

2. Maximized machine production time

The reduced setup phase also leads to increased productivity since the start-up process does not occupy the machine, and it can continue to be productive. The use of the Digital Twin thus saves twofold in terms of time and money.

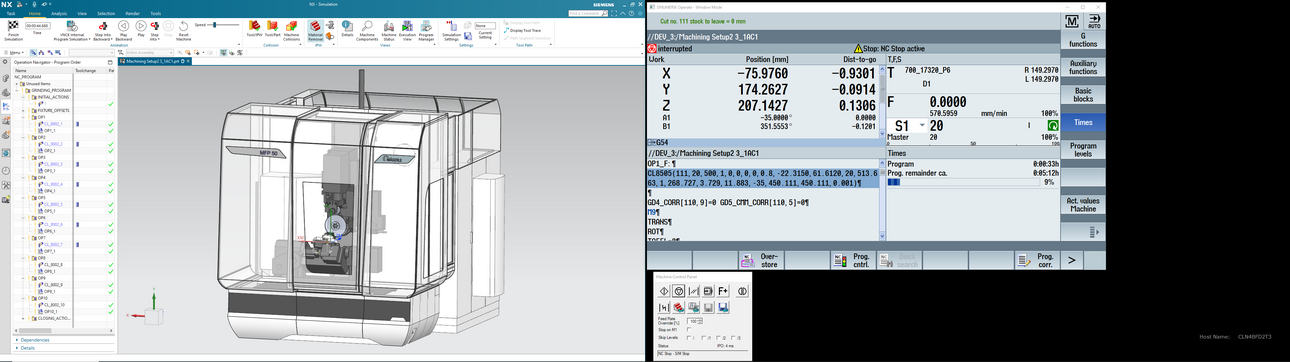

3. Training of programming and operating personnel without using a real machine

Because the Digital Twin provides a one-to-one representation of the machine's control system, the programming and operating personnel can be trained entirely virtually. This leads to an increase in the machine's production time and time savings and a schedule and location flexibility of the training.

4. Reduced risk of errors and damage

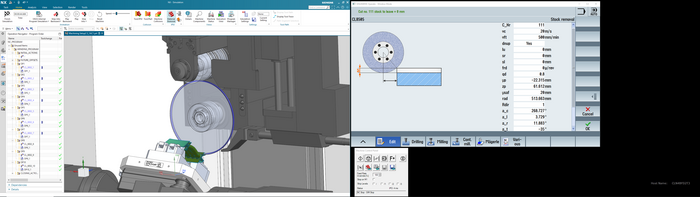

By simulating the grinding process with the help of the Digital Twin, errors can be corrected before they occur in reality. This virtually eliminates damage to the machine or workpiece— a major advantage, especially when it comes to expensive workpieces.

5. A better ecological footprint

Working in a virtual environment reduces the consumption of resources on the real machine. This not only saves time and money but also energy and other resources required for production. Therefore, the Digital Twin helps make the operation of your grinding machine more sustainable.

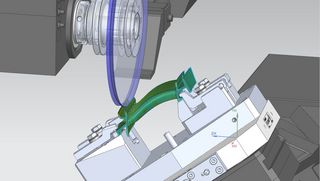

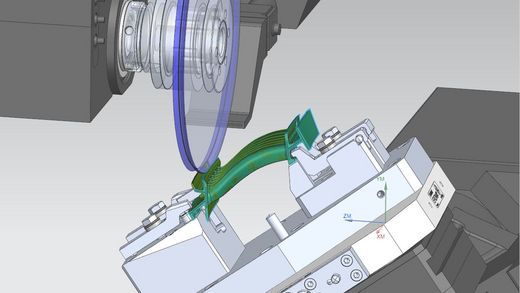

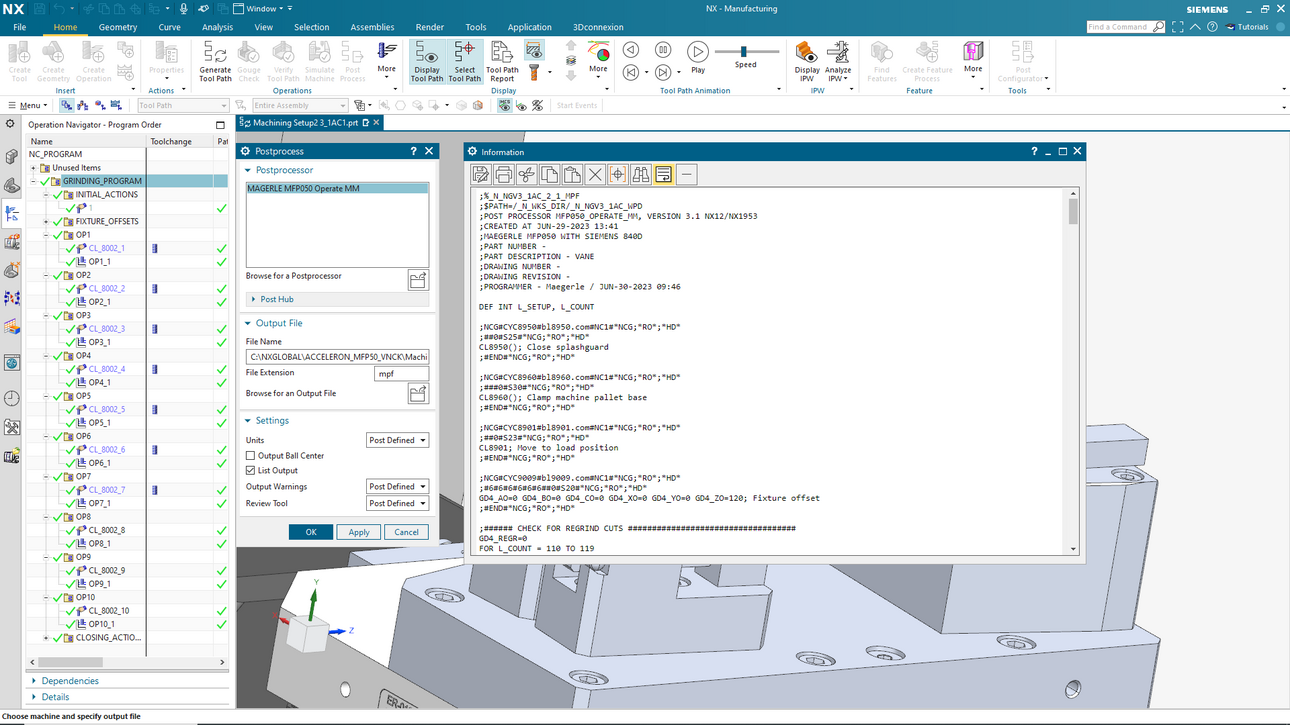

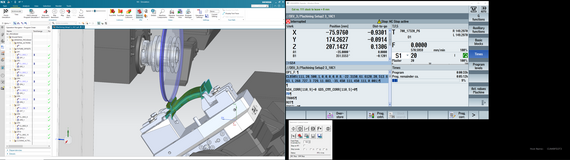

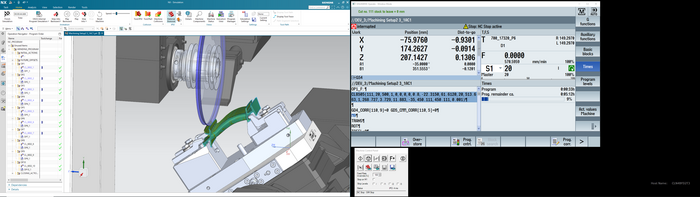

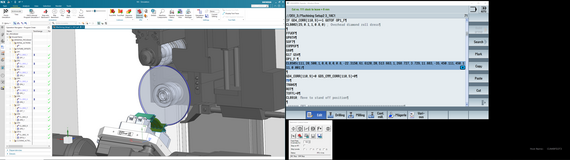

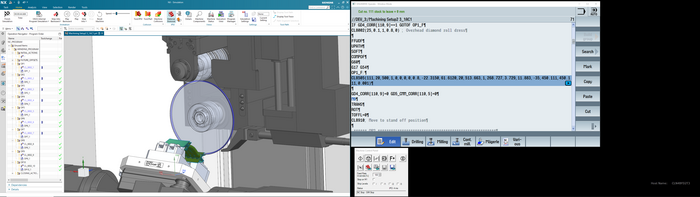

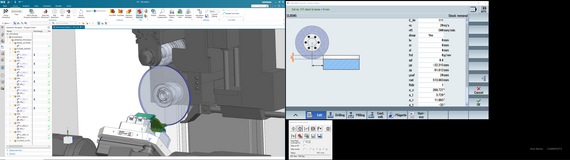

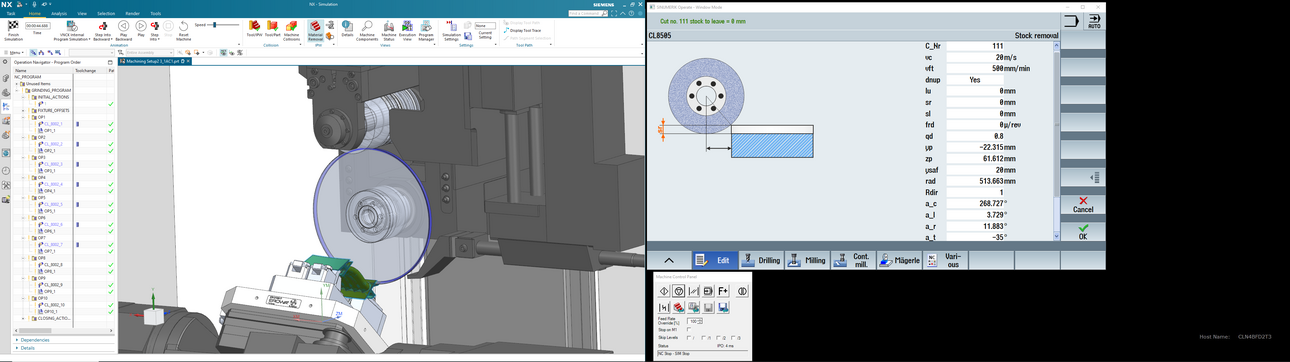

Digital Twin in pictures

Want to find out more?

Please contact us if you are interested in the Digital Twin concept. We would be happy to assist you.