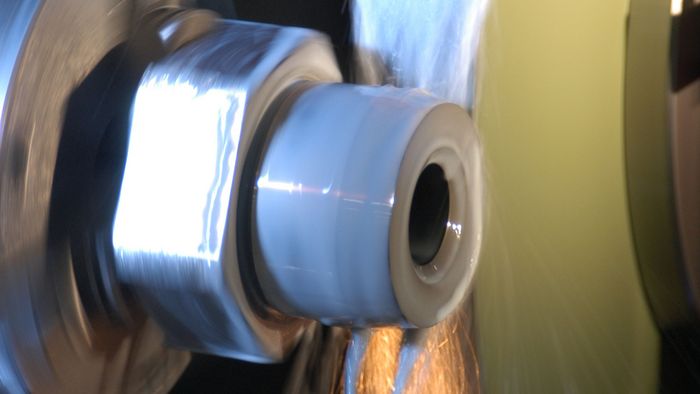

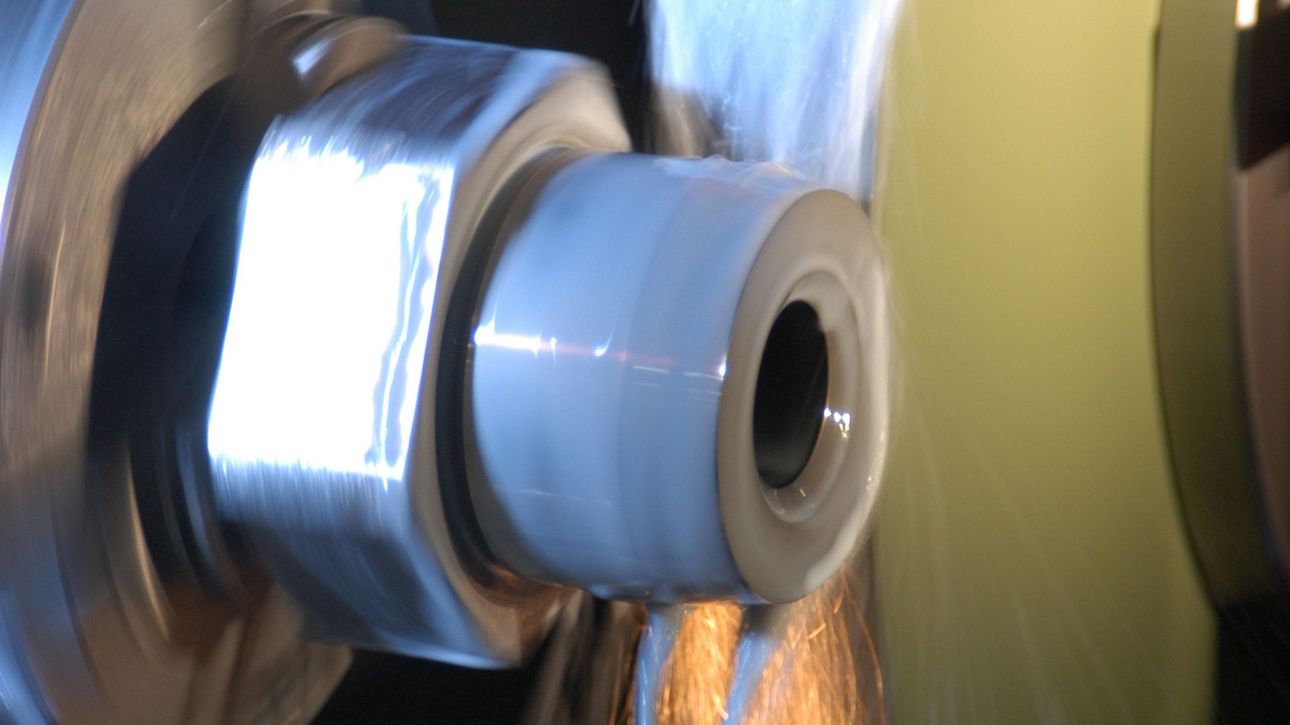

Several hundred parameters of a grinding machine determine the machining process for cylindrical grinding. A complex process, which is the preserve of absolute specialists. Or maybe not? The StuderTechnology computer breaks with this opinion, and also breaks records when it comes to grinding. Explained in simple terms, the software automatically determines all necessary data for cylindrical grinding. With just a few entries, the program calculates the production target and optimally grinds straight away with maximum feed. "It was clear to me for 13 years that as a turning specialist I would never be able to grind, too demanding a process. I was proved wrong. Thanks to StuderTechnology we can now grind complex parts. And bear in mind that we had no employees who could grind. It was a bold decision to invest in the STUDER S33 machine with StuderTechnology, but it was the best decision we have every made", Michael Jauer, CEO of Drehtech AG in Herzogenbuchsee (CH) is still passionate today.

Anyone can be a grinding expert with StuderTechnology

107 years of know-how

With the help of StuderTechnology, the operation of cylindrical grinding machines is radically simplified. Component quality, unit costs, machining time, energy efficiency, in short: all key production factors benefit enormously. What makes this software so unique? Its history! It incorporates 107 years of grinding experience. It combines formulas from grinding technology, empirical data and many years of expertise. The program contains data from countless grinding tests, in which the best machining strategy has been determined for a wide variety of components. Depending on the specific application, StuderTechnology uses these values and applies them appropriately. Think of a modern camera: You can select automatic programs for different lighting and photo motives. This results in a perfect picture in every situation. And of course you can also choose your own settings. StuderTechnology works in a similar way.

Up to 50 percent shorter machining time

With StuderTechnology you no longer have to be a grinding expert. It is incredibly easy to operate. "In principle, as a production specialist I need to know which parameters are decisive. The tolerances are crucial, on the one hand, and the surfaces on the other. I provide the grinding wheel specifications, the workpiece material and hardness, and decide whether the focus should be on fast infeeds or a good surface finish. On the basis of these values the software suggests the cutting sequence and cutting values. In the past I have always directly adopted the recommendations made by StuderTechnology. This has always worked, from the very first workpiece, without any rejects", explains Marcel Wagner, Production Manager at Drehtech AG.

The individual times can be drastically reduced. The grinding times alone are generally reduced by 25-50%. But set-up, programming and documentation times are also reduced by using the software. The operator no longer has to laboriously try to find the optimum value. The optimization time is eliminated in most cases. If you use the software consistently, the costs per part are considerably reduced. Or in other words - the production volume can be practically doubled with one and the same machine. As a welcome side effect the energy consumption is also positively influenced, which is why StuderTechnology has been awarded the "Bluecompetence" label.

Excellent solution

StuderTechnology has impressed experts since its launch. This innovation won the Prodex Award in 2012 and the INTEC Award in 2013. "The software is extremely fast and supports the process so effectively, that at the most, I only have to make an individual fine-tuning to the grinding parameters proposed by the program", explains Stefan Köhler, Foreman and Manager of the Grinding Division

at Pabst Komponentenfertigung GmbH. And what are the disadvantages of this unique STUDER solution? "Grinding machine operators are cautious souls and take a careful approach to machining. StuderTechnology goes all out", explains Daniel Zürcher, Customer Center Training Manager at Fritz Studer AG.

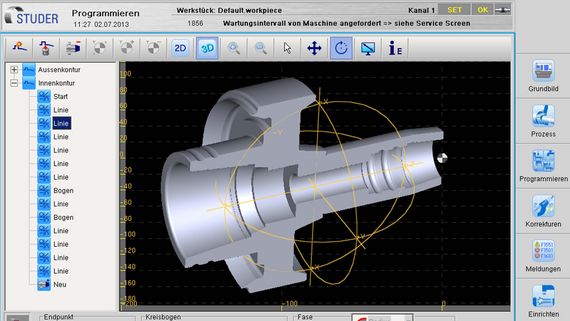

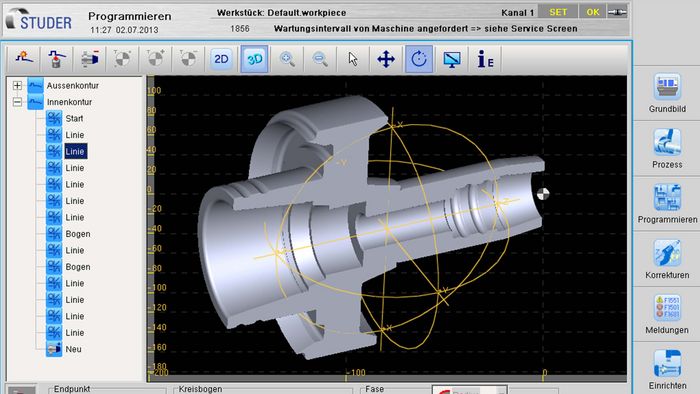

Function in detail

The starting point is always a workpiece drawing or a work proceedure. This shows the dimensional, form, position and surface tolerances. The user is repeatedly faced with the question of how he must set the machine, in order to fulfill the requirements. To be as quick as possible? Or as precise as possible? He must also include the material, hardness, grinding wheel type and cooling lubricant into his decision. From these variables he derives his setting values, which are characterized by personal experience, and thus his production goal.

StuderTechnology proposes such production goals. The production goal "Normal grinding" stands for applications in the tolerance range ~ H5/h5 and surface quality ~ Ra0.3. The production goal for increased material removal can be used for pregrinding operations in particular. The program provides two further production goals for higher precision or higher surface quality.

You can rarely achieve the optimum grinding result without support. A great advantage of StuderTechnology is that it takes account of the machine characteristics and the configuration of the grinding cycles. Grinding wheels and dressing tools have a longer life because only the minimum of abrasive is removed, which in turn results in less wear.

Conclusion: STUDER – "The Art of Grinding."

Grinding is an exacting science. StuderTechnology provides companies with a tool which anyone can use for grinding. Experts are also given accurate support. Thanks to the new Teach-In feature, operators can store their own programs.

The workpiece has better roundness and surface finish. Good quality and a fast, stable process are achieved at the first attempt, independent of the operator. Through the reduction of error costs, shorter grinding times, lower tool costs and the elimination of complicated calculations, productivity can often be increased by 50 percent. "The STUDER specialists told us that StuderTechnology would be a significant support to us in setting up and programming the machine. We were skeptical, as promises are easy to make. But everything that STUDER promised us was true. Perhaps even more so, which was really impressive", acknowledges Marcel Wagner.