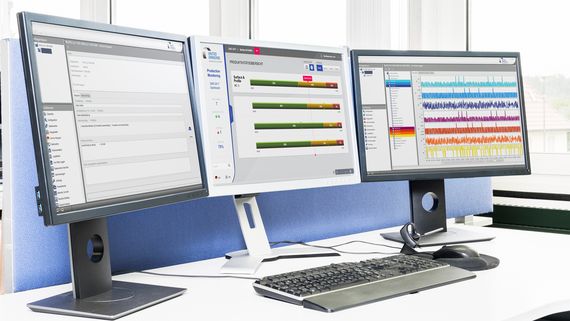

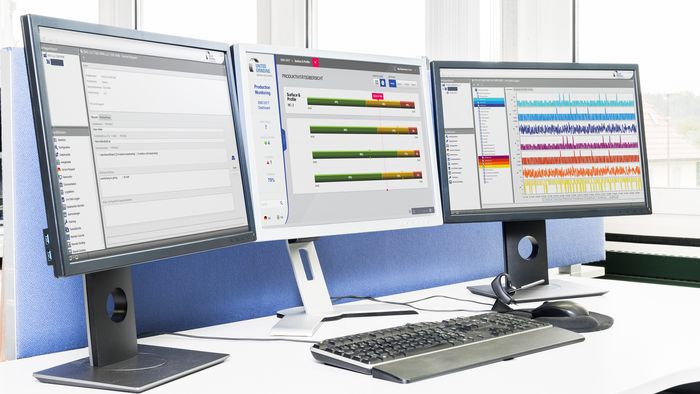

The Production Monitor is a reliable 24/7 monitoring service. The customer has always and everywhere the overview of his machine park. Running times, non-productive times and disruption times are available in real time. This data allows you to optimize production in terms of utilization and availability, thus supporting the production managers, planners and production staff. What is the goal of the Production Monitor? "Today, a suitable tool is often missing to visualize the utilization of the machine. The Production Monitor offers just that transparency, "explains Daniel Renfer, project manager at STUDER. This practical tool can be displayed on different interfaces, for example on an app or on a web browser. Another advantage: On the Production Monitor the customer can configure the machine park based on his needs. Everything is possible, from detailed information of an individual machine to the complete overview of the entire plant.