STUDER focuses on its strengths

With its new image campaign, STUDER is focusing on its motto "The Art of Grinding." and talking about what the company does best: The art of grinding!

The health crisis around COVID-19, the brexit, global trends towards trade restrictions and customs barriers, the structural change in the automotive industry: 2020 is and stays a challenging year. "Testing", is the word used by Sandro Bottazzo, Managing Director of Fitz Studer AG and as CSO responsible for Sales, Customer Care and Marketing. And in a situation like this a company should focus on its own strengths, Bottazzo is convinced. "We shouldn't worry about what we can't do, but we should talk about our strengths."

Where do these strengths lie? "We have unparalleled knowledge in and around grinding", says Sandro Bottazzo. "Grinding is more than just machining." You have to master all the parameters. If you are in control of all those, then you have mastered "The Art of Grinding.". "Nothing says more about us than our company motto", says Bottazzo. That's why STUDER is refocusing on this motto.

The Art of Grinding

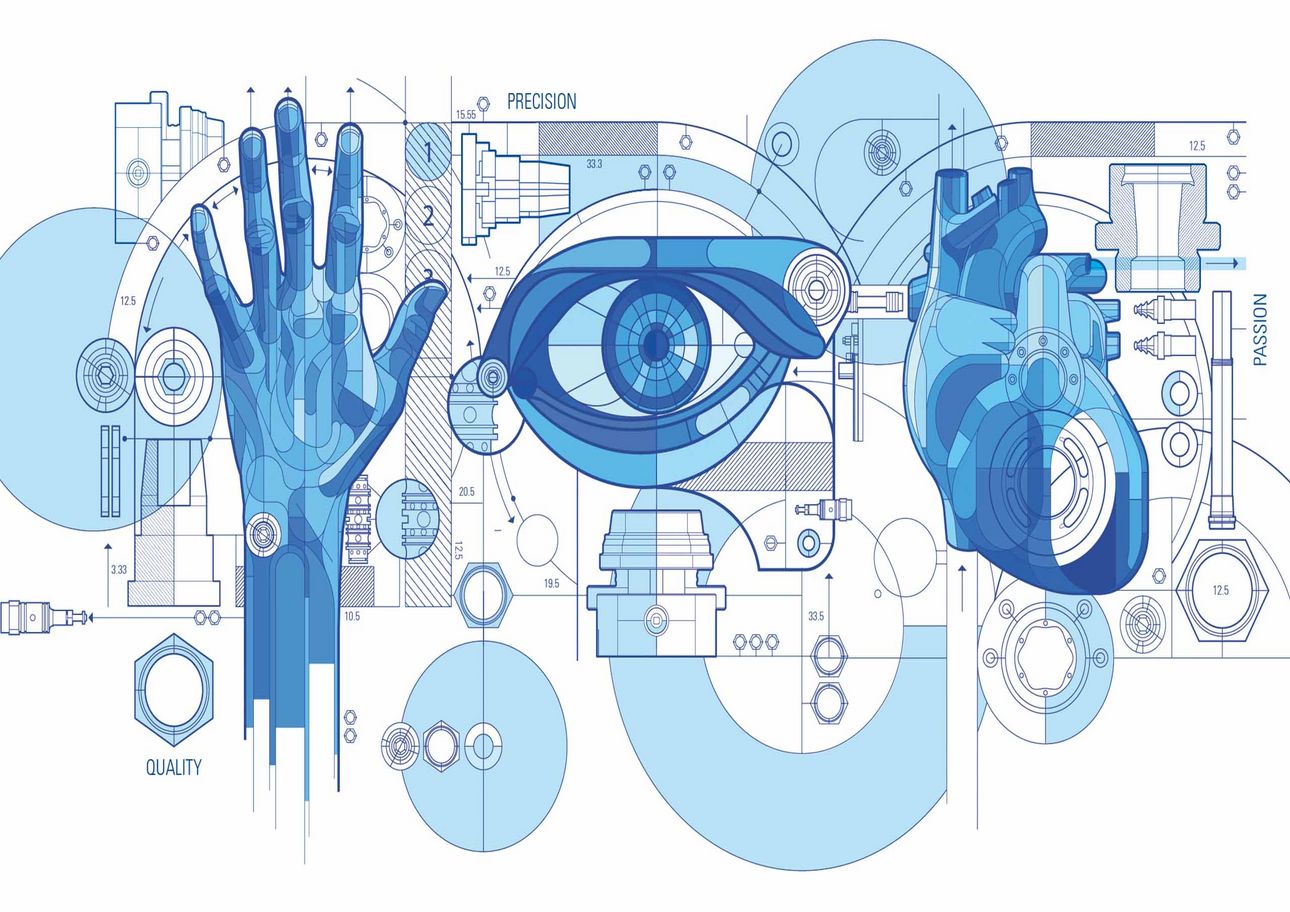

The new campaign also refers to the world of art. At the Motion Meeting in February 2020 STUDER presented an S31 artistically designed by Swiss artist Ata Bozaci, which will also be shown at future trade fairs and exhibitions. Ads and mailings have also been co-designed by Bozaci. "In recent years we have concentrated increasingly on product promotion and are now consciously pursuing an image campaign, despite the current difficult economic environment", explains Bottazzo. Ata Bozaci has designed key visuals for STUDER's three fundamental values: Quality, precision and passion.

They want to make an impression with this campaign, explains Bottazzo, and show courage. Even in these challenging times. This courage naturally also stems from the company's successful history, spanning more than 100 years. But they don't want to rest on past successes, emphasizes the CSO. A large number of projects and investments have already been pushed forward, with the aim of further improving machines and services, as well as company processes and communication.

Machines, services and company processes

Fritz Studer AG is continuing to invest in its Steffisburg location: Three highly automated, networked 5-axis milling centers are now in full serial production and are producing more than 400 different, complex machine components, partially unmanned. Consistent use of the latest machine, tool and process technology enables the highest precision requirements to be fulfilled efficiently and in the best quality. In Customer Care customer service is being further optimized, by incorporating a third tier between the Regional Service Manager (First Level Support) and Technical Support (Third Level Support), among other things. This so-called Solutions Support (Second Level Support) enables even faster and better service.

Internally, the PuLs® initiative is being expanded and further intensified in collaboration with the other brands of the UNITED GRINDING Group. All STUDER employees also have the opportunity to engage in open exchanges with the STUDER management in so-called Town Hall Meetings. "These meetings began in 2019 and had a fantastic reception", emphasizes Sandro Bottazzo. "This is the beginning of a new and even more open culture of discussion."

"Quality means fulfilling customers' expectations in every respect. This quality is defined by the requirements placed by a STUDER customer on our products and services", explains Stephan Stoll, COO of Fritz Studer AG. STUDER measures quality not only on the basis of quality costs, measuring documents and checkpoints, but also places a strong focus on customer satisfaction and the number of repeat orders. "To ensure the required quality, every single employee must be aware of the overall concept of quality, and each one must ask themselves, where is my contribution to this", says Stephan Stoll. Bottazzo adds: "We have been measuring the satisfaction and recommendation rate of our customers for years using the Net Promoter Score®. This is an important tool for receiving permanent feedback". The results are analysed and interpreted monthly at STUDER in order to promptly define and implement improvement measures.

"Precision means the quality that a workpiece needs to deliver at the right time, in the right place. This doesn't just relate to fundamental parameters such as dimensional stability and the required form and position tolerances. All types of environmental influences must also be taken into account: Coolant, sensor technology, vibrations, climatic conditions, as well as the precision of bought-in parts", explains Alexander Heiter, Head of Mechanical Production. In mechanical production work is carried out in a range of less than one micrometer, or a thousandth of a millimeter - but interestingly, the highest precision is still produced by people and not by machines. "During the scraping process highly experienced employees work components to the required flatness and angularity using scrapers. No machine can do this so precisely", explains Heiter.

"Passion has to do with persistence. You don't instantly applaud the first result, but look to see how it could work even better. Passion is connected to the demand on quality of work. I believe this is central for STUDER. If 100 percent of all employees can agree on one thing, then that's quality. With our corporate and lean philosophy, PuLs®, we are constantly optimizing our processes", says Daniel Renfer, Head of PuLs® Lean Management at Fritz Studer AG. Renfer see another sign of the passion in the company in the employees' huge loyalty towards their employer, and vice-versa. "It is quite remarkable that many employees have been with us a very long time. And passion also means that when the going gets tough, when push comes to shove, you stand together and do much more than the average", adds Renfer. Bottazzo concludes: "We have some employees who have been working in the company for over 35, even 40 years or more. And many even did their apprenticeship at STUDER. Like Daniel Renfer, for example, and me too!".