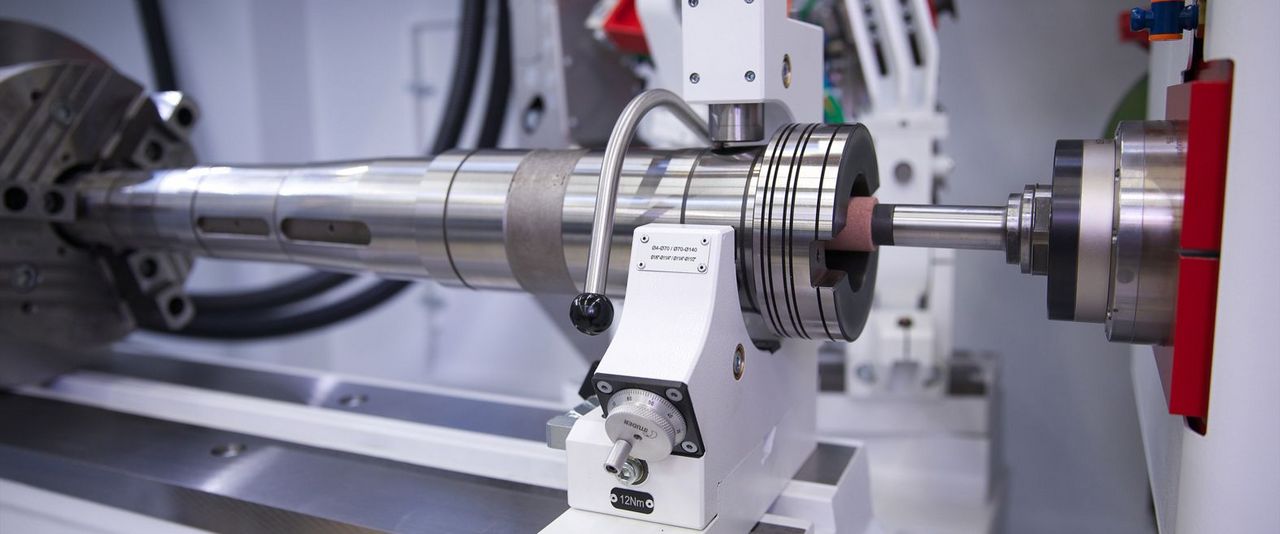

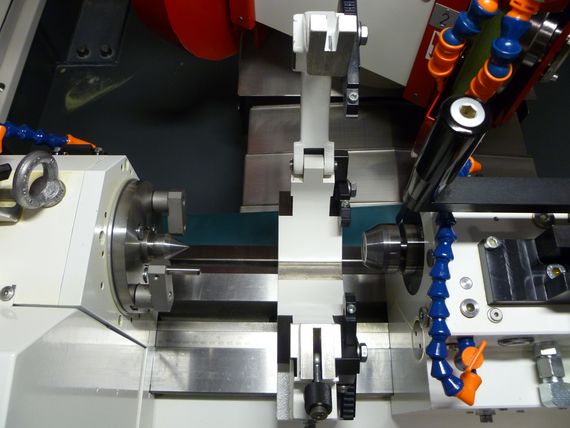

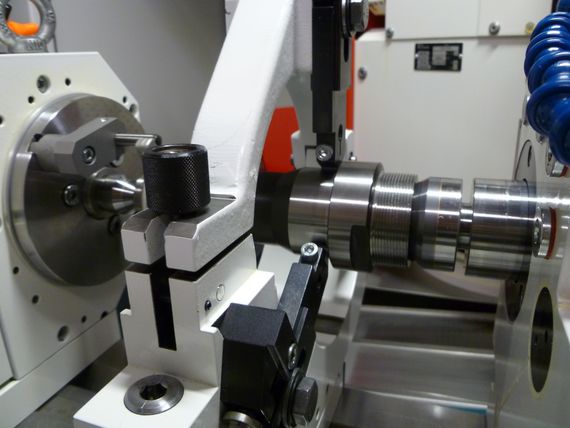

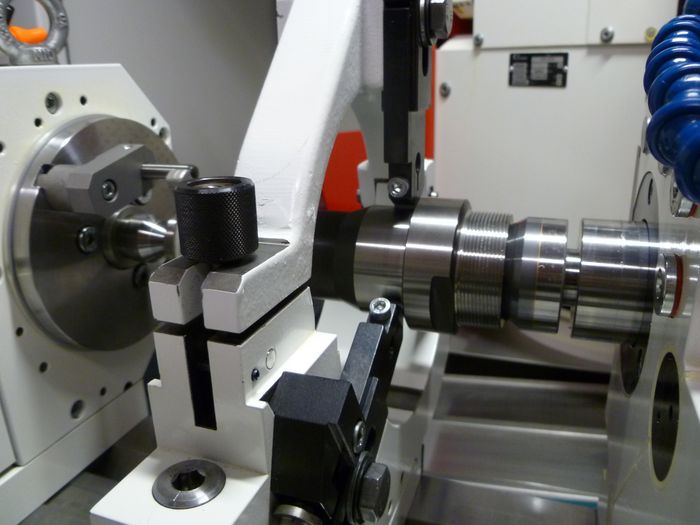

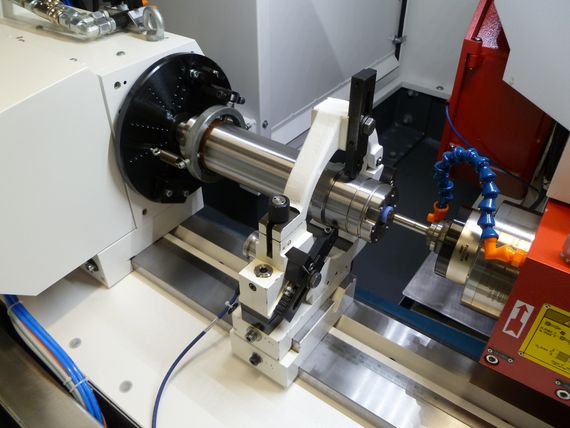

Cylindrical grinding with a closed steady rest

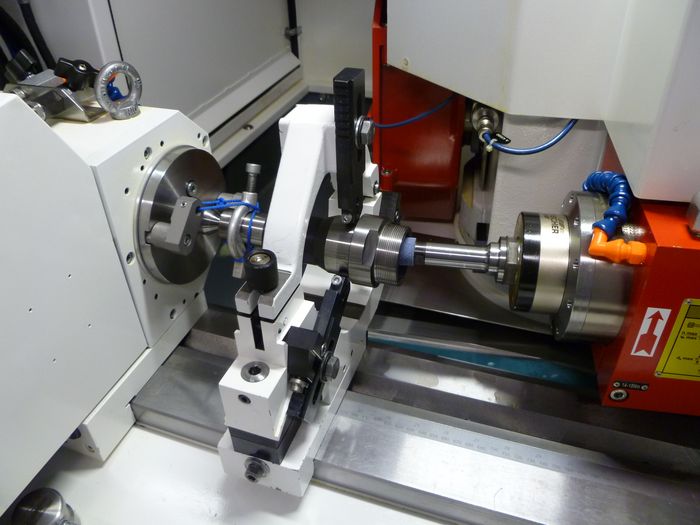

During internal grinding the closed steady rest is used for mounting long workpieces, which are held by the workhead center on one side. The fine adjustment feature allows correction of cylindricity and conical errors, without having to adjust the jaws.

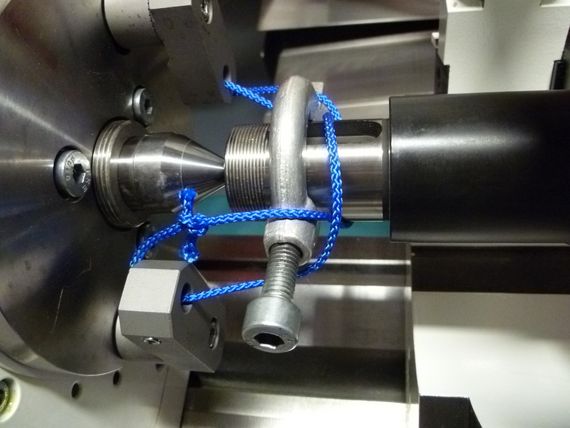

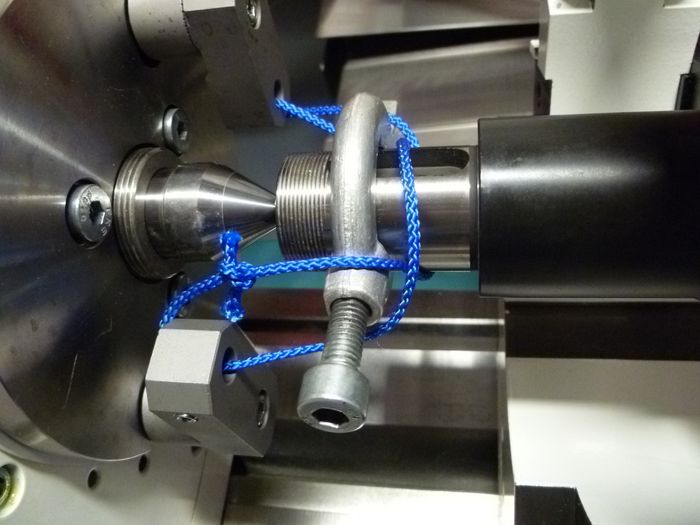

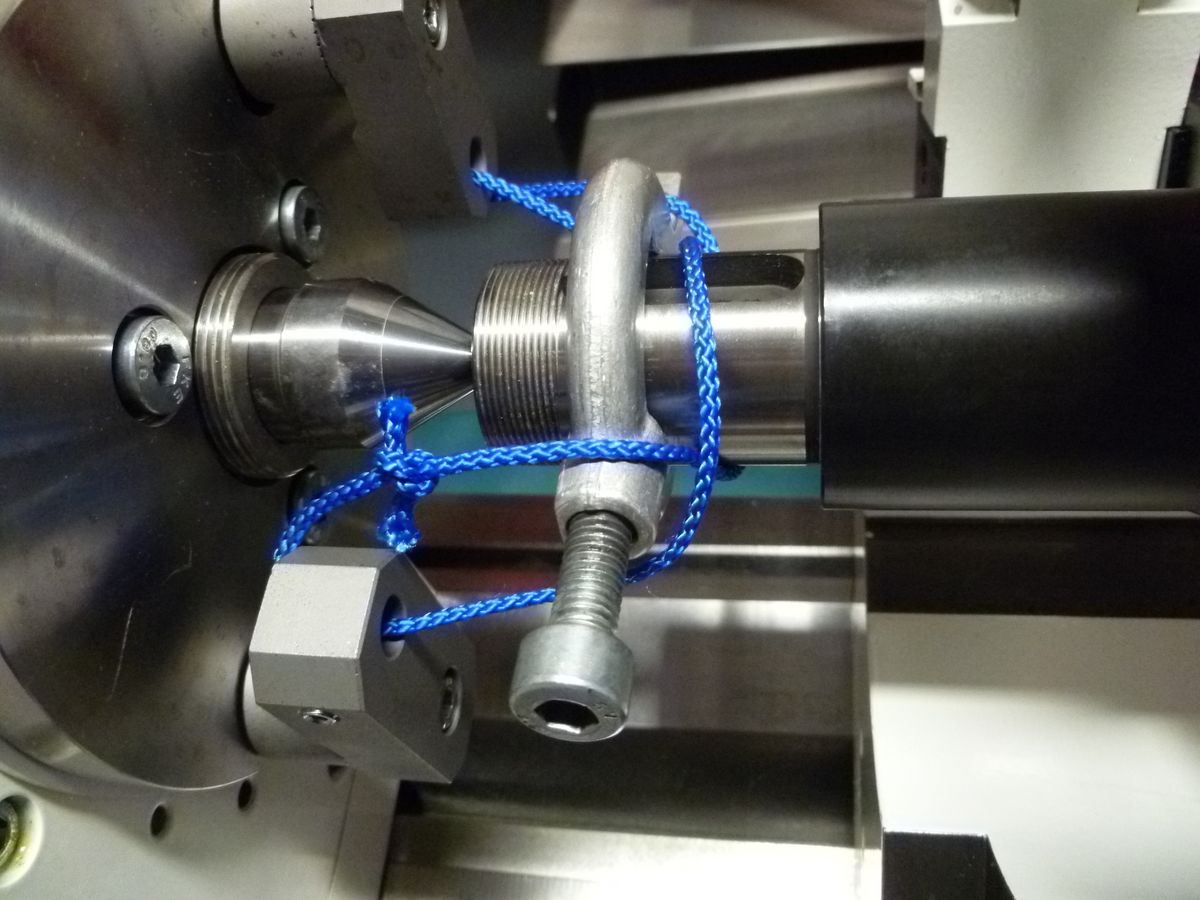

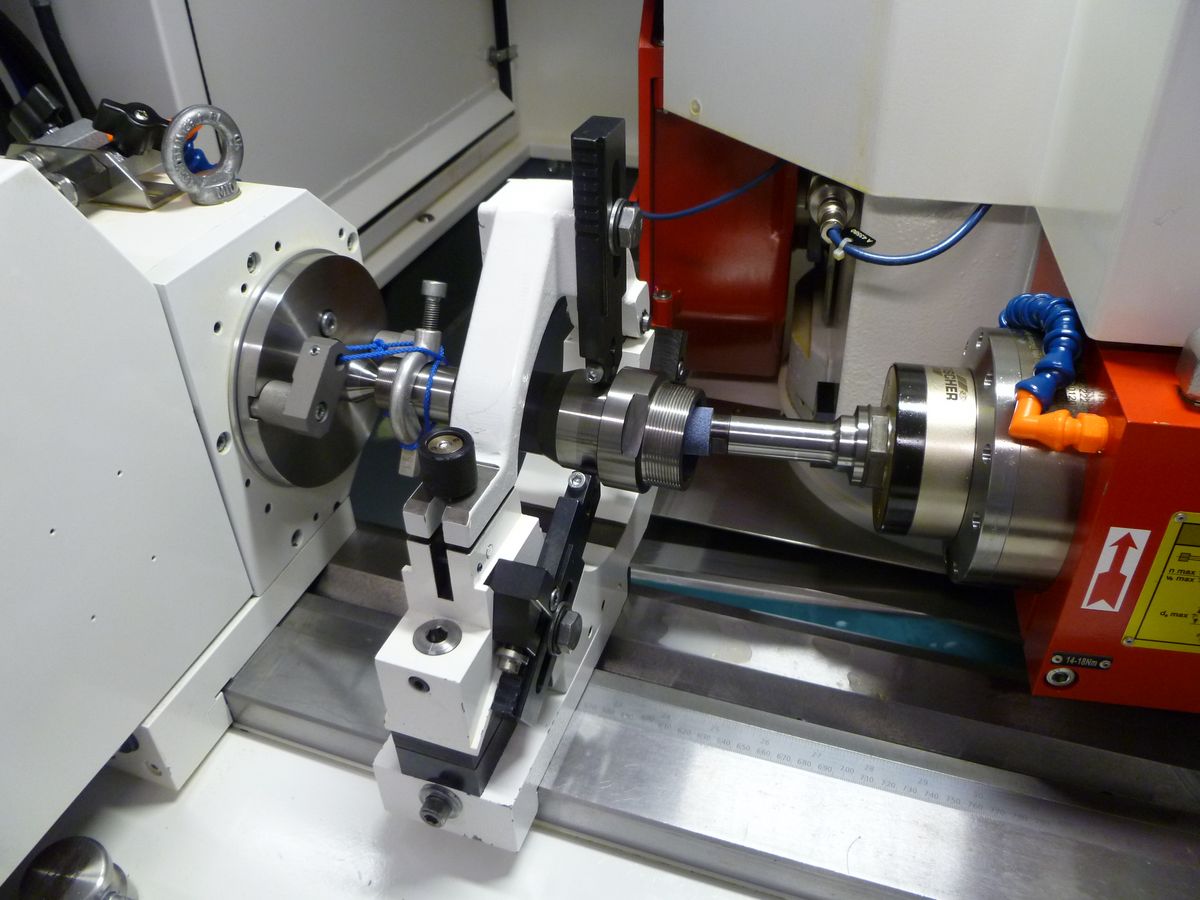

"Rope trick"

The "rope trick" is a way of simultaneously driving parts, which are clamped with a center and steady rest, and pulling them back onto the center. The condition for this is that the center can be locked. This variant is primarily intended for small to medium-sized components.

Procedure:

First of all the parts must be ground between centers. The steady rest seat must present a minimal tolerance, so that it can subsequently achieve correspondingly precise form and position tolerances.

When the external grinding operations are complete, place the steady rest in the desired position.

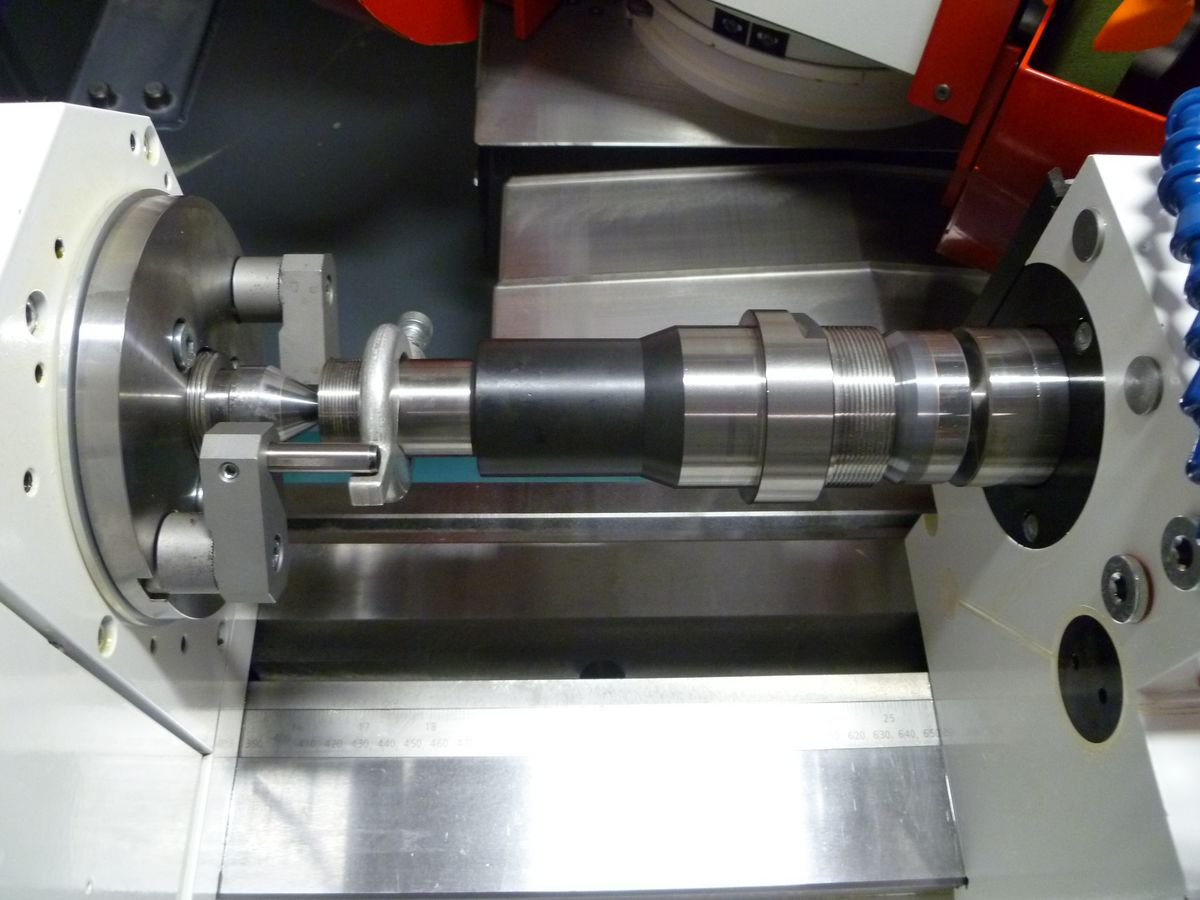

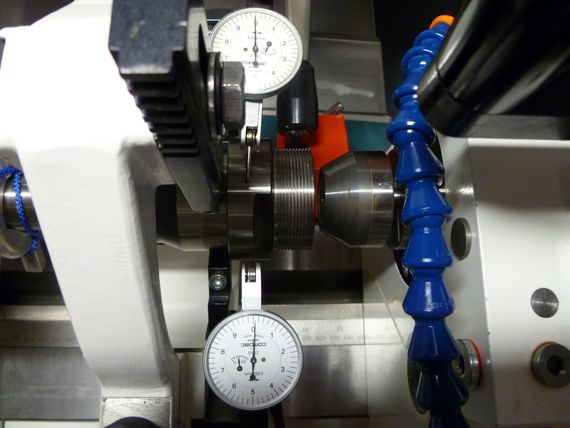

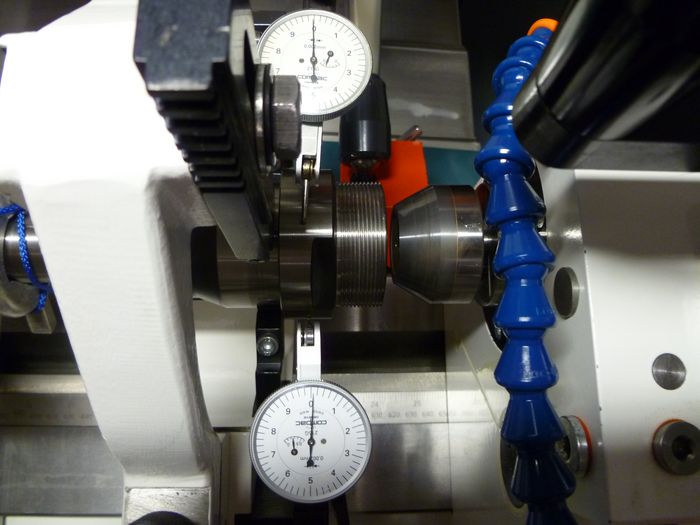

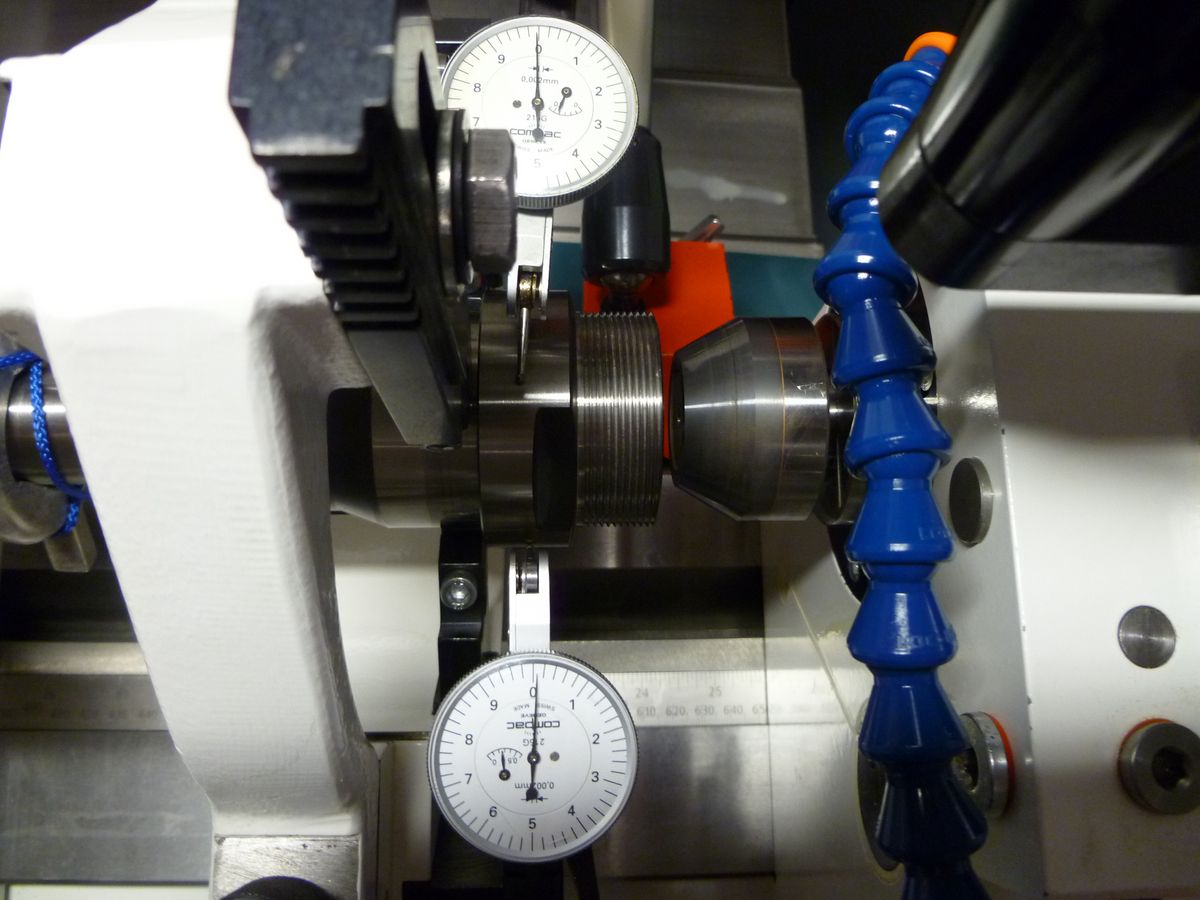

Clamp workpiece between centers again. Now carefully set the two lower jaws to the ground steady rest Ø and tighten. Adjust the upper jaw so that the clamp is not completely closed, so that a light pressure can be exerted with the sprung knurled-head screw.

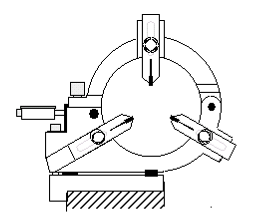

Now thread a rope in crosswise between the two locking head drivers and the grinding heart, as shown. Do not over-tighten, so that the workpiece can be removed again and later reclamped without loosening the rope. The part is then pulled onto the center by twisting.

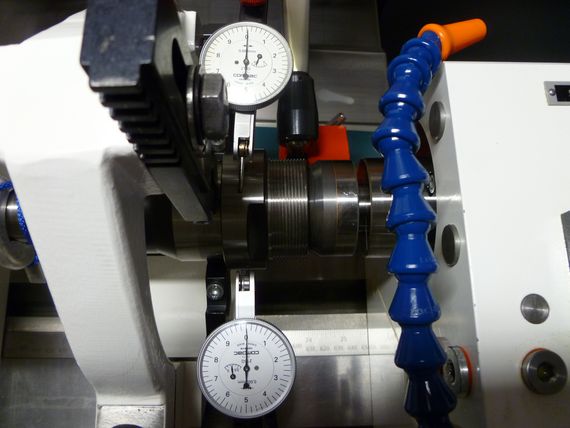

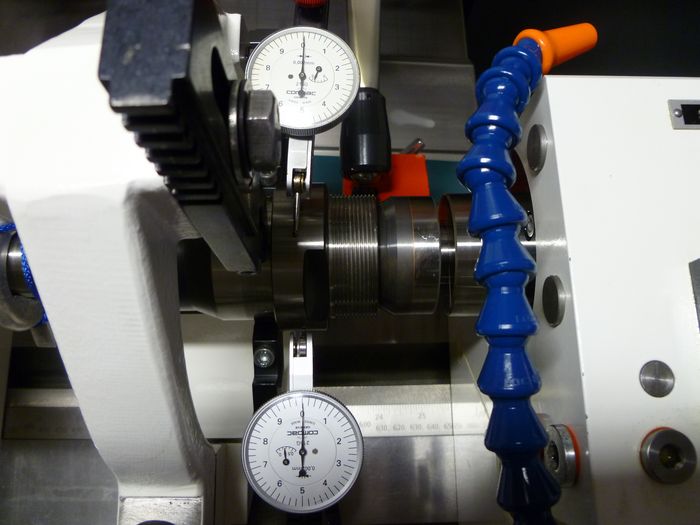

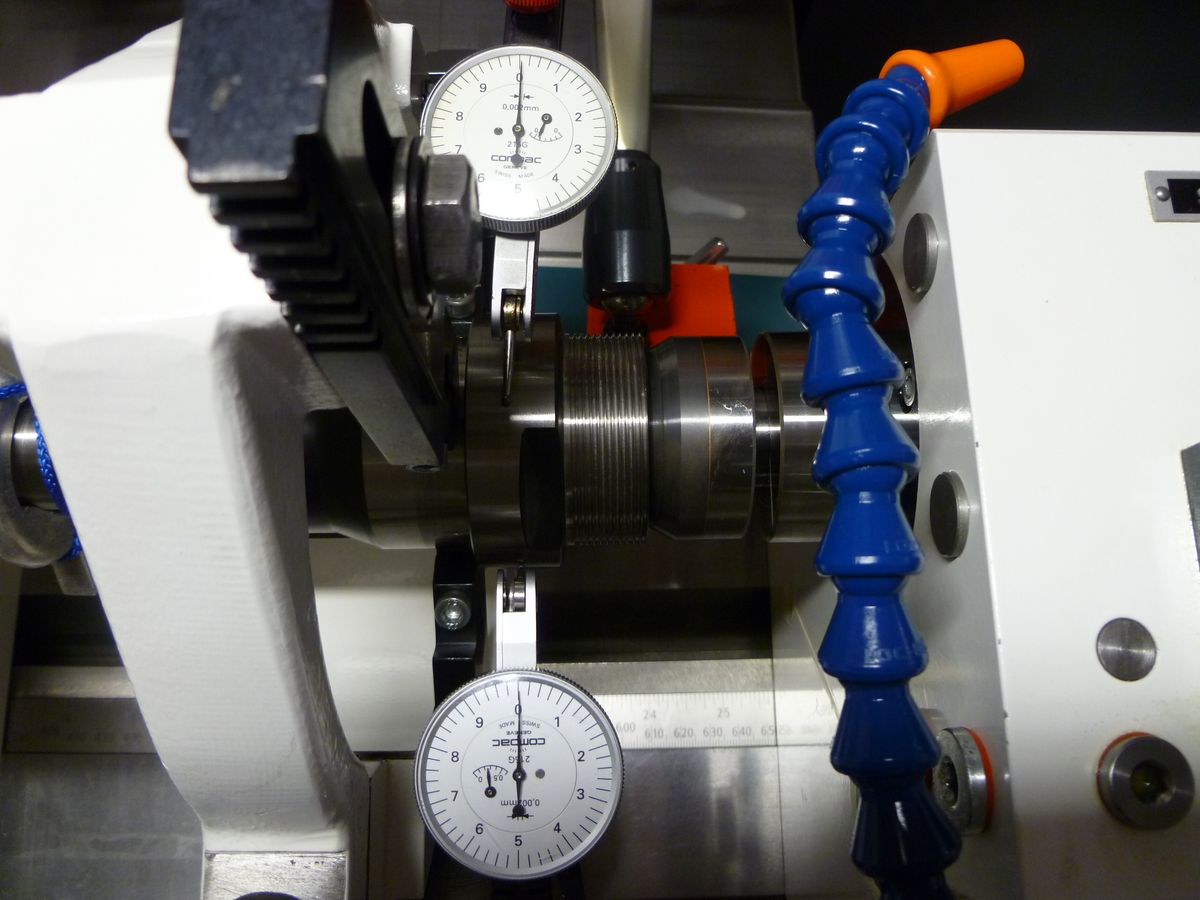

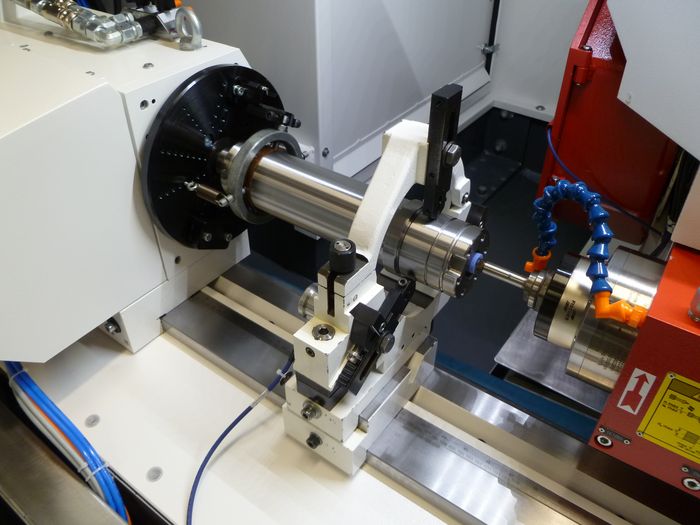

A dial indicator must be applied at the top and side, to ensure that the workpiece is correctly positioned. The tailstock center remains in position during this process.

The tailstock center can now be removed. If the indicator pointers do not move, then the steady rest is correctly set and ready for grinding.

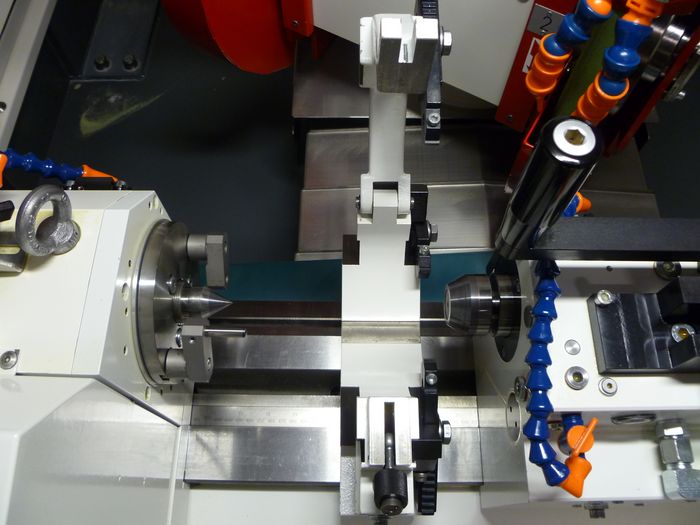

The tailstock can now be removed, so that the machine is ready for internal grinding operations.

Note:

Flood the steady rest position with coolant if possible or at least sprinkle with a thin film of oil. The steady rest will always make a small track. However, this is hardly measurable and a visual problem at most. If this track is unacceptable, the steady rest position must be pre-ground and finish-ground after internal grinding - clamped between centers again.

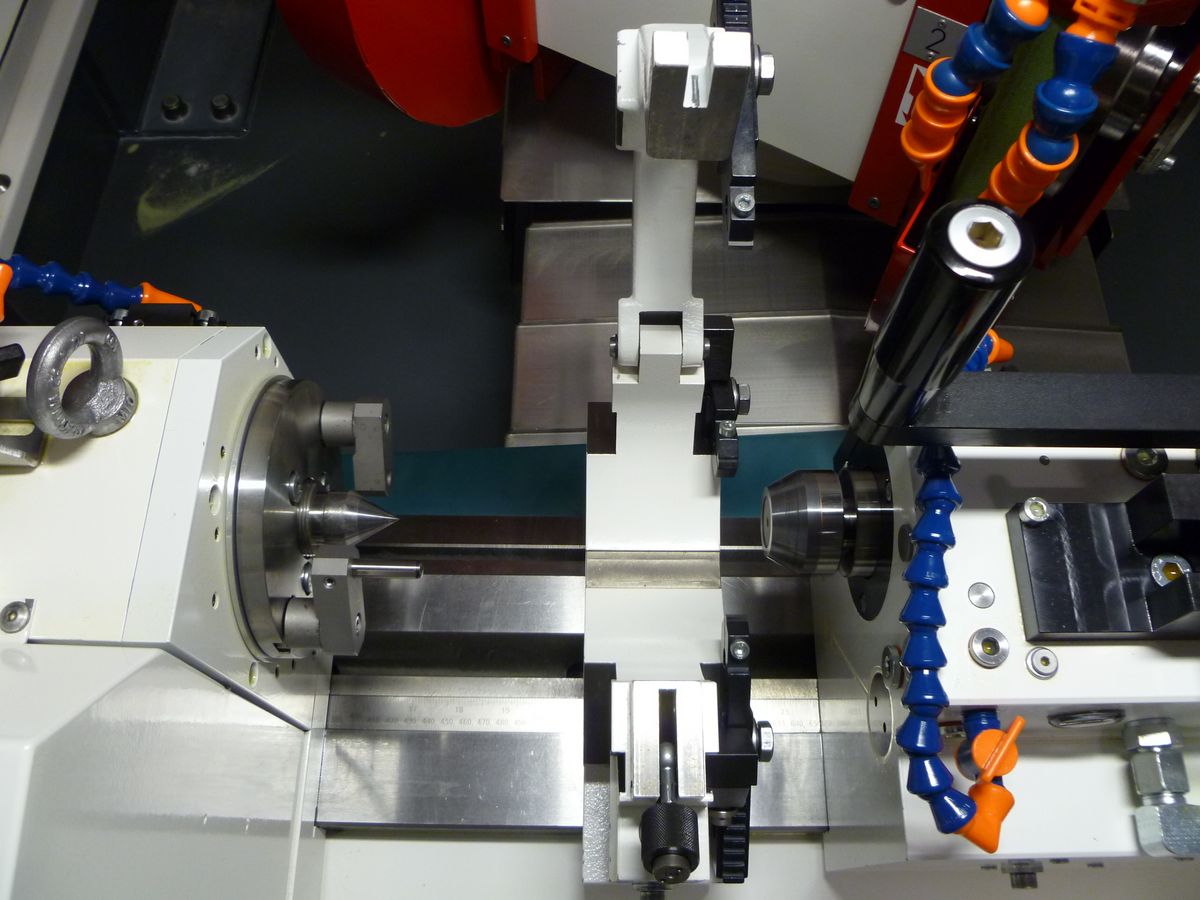

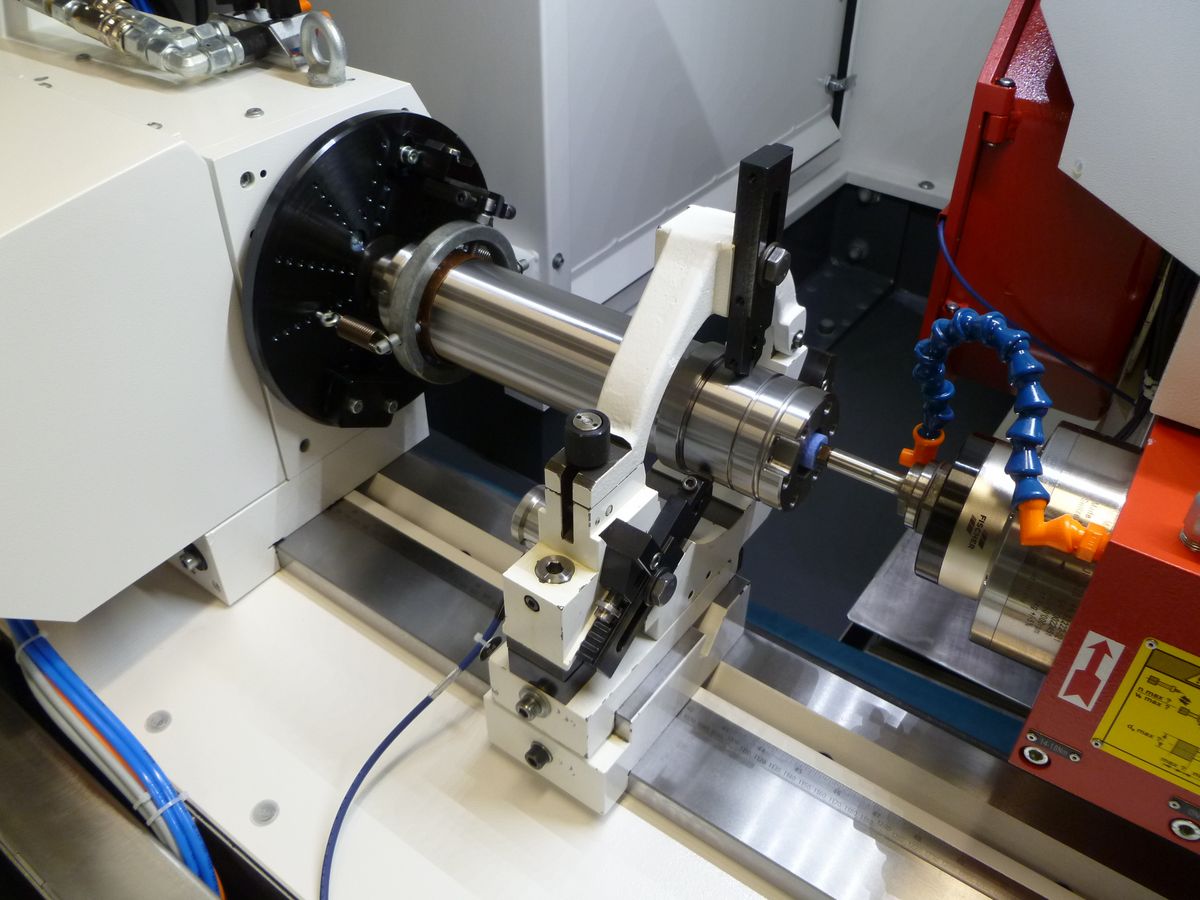

In the case of machines which cannot lock the workhead center and with heavier components, variants with tension or compression springs are used. In these cases an additional drive must be ensured.

Clamped workpiece in the tension spring version.

With compression springs a larger retracting force can be applied to the center.

Do you have any questions?

If you require further information, please contact us. We will be happy to advise you.