The advantages of a universal cylindrical grinding machine for high-precision manufacturing

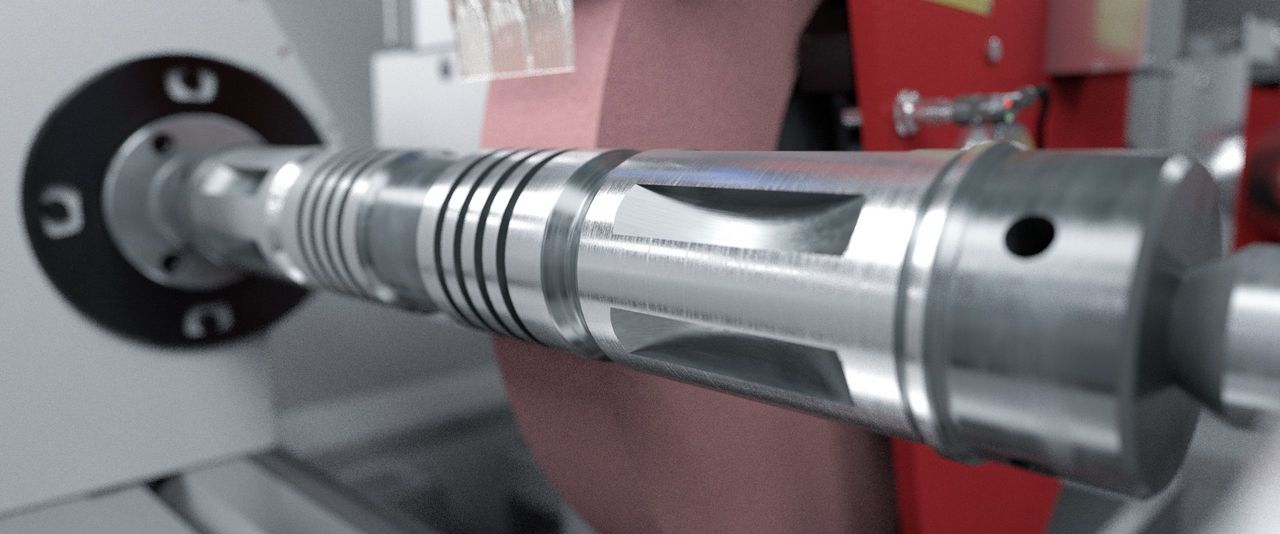

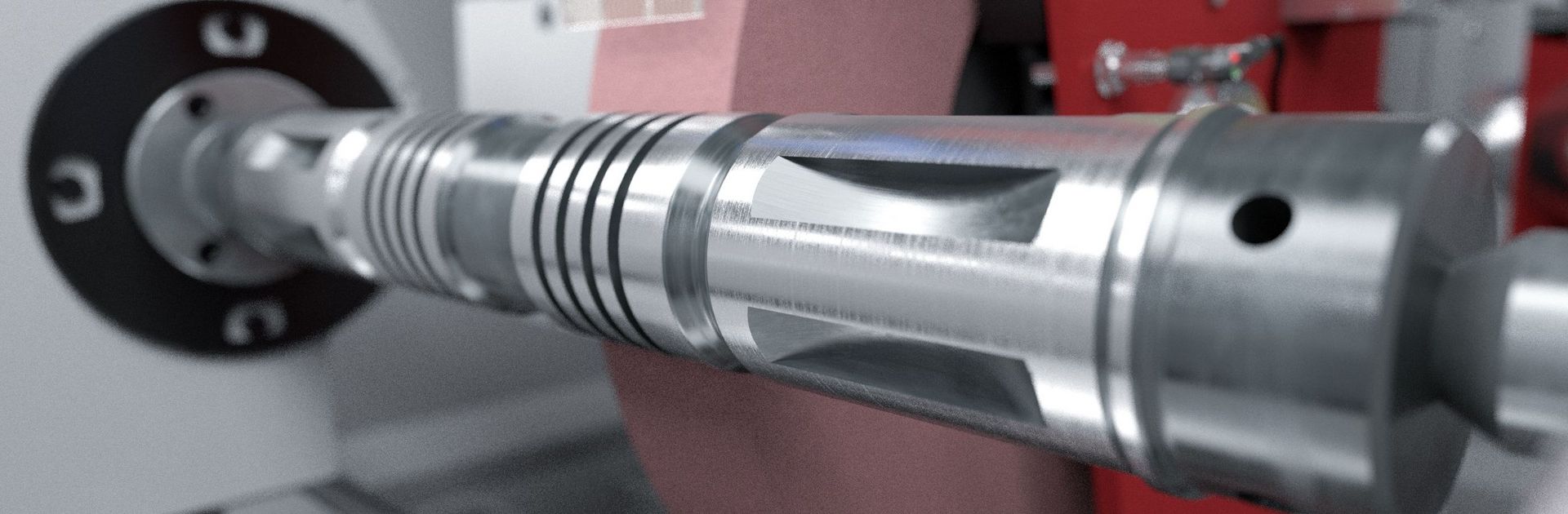

In recent years, the technology in universal cylindrical grinding has made significant progress. Modern machines offer greater flexibility and easier operation. For example, STUDER internal and external cylindrical grinding machines can accommodate up to four grinding wheels with different combinations of internal and external spindles. This enables a single clamping for many complex processes. Today, a modern universal cylindrical grinding machine makes it possible to do in a single operation what previously required up to five machines. This even applies to difficult-to-machine materials and tight tolerances. This is made possible by advances in software, grinding wheel technology, calibration processes, and built-in measuring functions. In today’s blog, we will go into more detail about the advantages of a state-of-the-art universal cylindrical grinding machine.

First, we would like to briefly highlight a few of the potential grinding operations that are possible on universal cylindrical grinding machines:

- Internal cylindrical grinding

- External cylindrical grinding

- Shoulder grinding

- Taper grinding

- Face grinding

- Plunge grinding

- Grinding of surfaces/flats

What does this mean for the different industries? Here' are a few examples:

- Manufacturers in the aerospace industry can use a universal cylindrical grinding machine from STUDER to maintain tight tolerances on difficult-to-machine materials, for instance, when processing non-circular forms such as squares and hexagons.

- Bearing manufacturers can grind the bearing ring's external and internal diameter without reclamping the workpiece.

- Large workpieces, such as shafts and gears, or small parts, such as ball screws and threads, can be ground in a single clamping.

Many manufacturers use materials that are difficult to machine. The flexibility of STUDER universal grinding machines is particularly well received when machining workpieces with a high-mix and low-volume (HMLV).

Automation options for universal grinding machines

The floor-to-floor time increases as soon as it is necessary to open the grinding machine door for additional handling or measuring procedures. In this process, errors may occur. Reducing the handling and transport of parts improves quality. This also allows operators to work on several machines at the same time.

The automation of universal grinding machines includes clamping, marking, washing, demagnetizing, deburring, measuring, and laser processing. A STUDER universal grinding machine with the appropriate loading system can contribute enormously to productivity.

Advances in probes and software improve adjustment possibilities and quality

The latest universal cylindrical grinding machines feature advanced measuring systems that can measure multiple diameters with repeatable accuracy. This allows the part to be pre-ground and then measured by the measuring system and, if necessary, a correction to the program for the finishing operation. The grinding software is becoming more powerful and, at the same time, also becoming more user-friendly. This makes it easy to adjust workflows and cut the learning curve for new operators. It is also possible to program applications while the machine is running. |

The flexibility of universal grinding machines also offers more options for the use of grinding wheels

The flexibility of universal grinding machines also offers more grinding wheel options. Multiple spindles allow high material removal with one wheel and a medium and finer operation in the same clamping, thus frequently eliminating the need for a separate finishing step.

Thanks to the option of the swiveling wheelhead, complex geometries are possible with straight wheels without having to change to a profiled wheel. Straight wheels are generally cheaper and more likely to be in stock. They are also easier to dress.

Another example of the many potential uses of a universal grinding machine: workpieces produced for the aerospace industry. A carbide coating requires a diamond grinding wheel, but the workpiece is alloy or steel and requires a different grinding wheel. A multi-spindle universal grinding machine can machine the entire workpiece, eliminating an additional setup and associated issues.

Thermal stability and an eye on geometry

STUDER offers a wide range of universal grinding machines for machining workpieces of different sizes.

STUDER focuses on thermal stability in all machines, as this enables tighter tolerances and more accurate results. Even opening the doors of a grinding machine to remove parts can cause temperature control issues. STUDER offers the option of running all spindles simultaneously so that they remain warm and ready for use to reduce dimensional fluctuations. Temperature control applies not only to the spindles but also to the entire machine base and machine elements to ensure a more stable process.

You can find out more about STUDER internal and external cylindrical grinding machines here.

Want to learn more?

We would be happy to assist you. Contact us