WireDress® - When grinding receives an unprecedented dimension

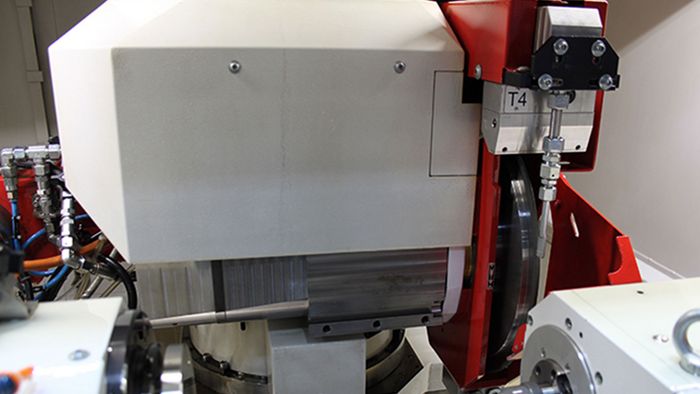

Alfred Mair, Head of Grinding Technology at Fischer in Herzogenbuchsee, faced a challenge. The aim of Fischer AG was not only to increase productivity, but they also reached their limits in the grinding of exotic materials such as titanium and hard-to-machine hard materials under the increasing quality demands from the customers. He could not solve the problem with a conventional grinding machine. What next? The solution was closer than suspected: just 60 km away, at STUDER, a company based in Steffisburg. Here the CNC universal cylindrical grinding machine S41 is manufactured. Specifically designed for large workpieces, it has a length between centres of 1000mm (40") /1600mm (63") and a centre height of 225mm (8.9") / 275mm (10.8"). With linear direct drives, it processes workpieces with high precision up to a maximum weight of 250kg (550lbs). Of course, the S41 is also just as effective with small and medium-sized workpieces. But the key for Fischer is the fully integrated WireDress® dressing system. "We had high hopes that we could use metal-bonded grinding wheels, have a higher productivity, more universal machining options as well as reduced tool costs," Mair explains his expectations.

Expectations exceeded

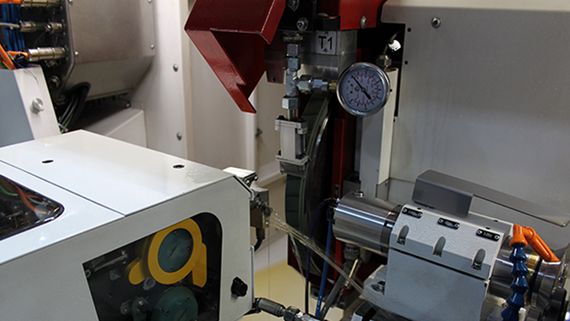

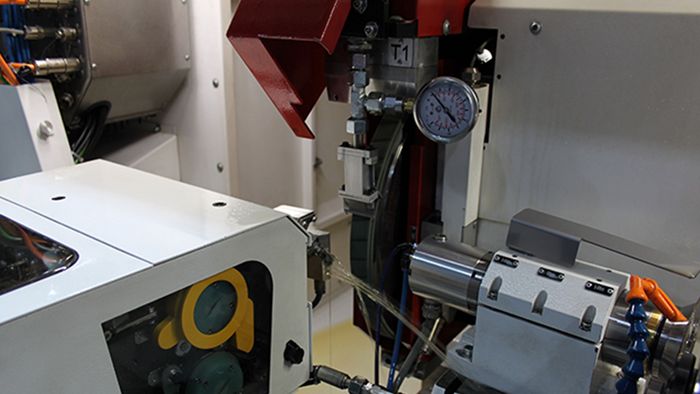

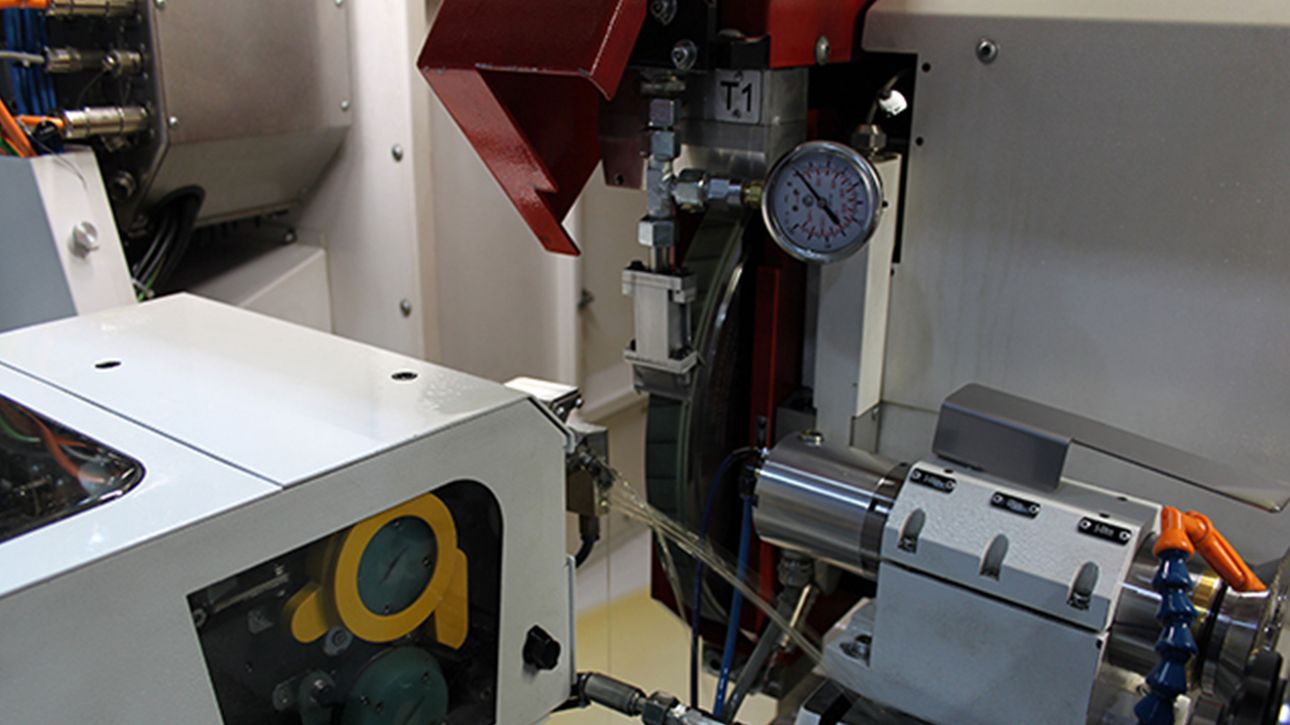

STUDER configured the S41 with WireDress® based on additional wishes of FISCHER AG. Thus, the machine received a special high-speed external grinding motor spindle, an innovative proprietary product of FISCHER AG, in which the axial growth is particularly small. In addition, the spindle is tapered at the rear end, avoiding possible collision situations. This is a specific benefit for face/shoulder grinding with the spindle at an angle. The S41 is supplemented with a fully automatic workpiece magazine and handling system, which ensures fully automatic series production of the high-quality precision components in a stand-alone operation. The conclusion of Mr. Mair after a solid introduction time of the machine:

The secret behind it

But how does this dressing technology work? Michael Klotz, project manager for development at Fritz Studer AG, explains it this way:"It is a well-known fact that metal-bonded grinding wheels are much more durable and dimensionally stable when machining difficult-to-machine materials and ultimately enable higher productivity. The problem with this is that metal bonds can only be dressed to a very limited extent using conventional methods in the grinding machine. In addition to this there is a high dressing tool wear associated with a low cutting ability. This is neither an operator-friendly, nor a high quality and process consistent dressing method”. This is why the "best" bond – the metal bond – is rarely used.

"STUDER has developed, along with technology partners, the machine-integrated WireDress® dressing technology. Here, the dressing is done at full wheel speed. In contrast to conventional mechanical or external EDM dressing, WireDress® dressing occurs by using a modified wire erosion in the grinding machine, where the grinding oil serves as a dielectric. The dressing process is contactless and wear-free. The grit itself is not dressed, the metallic bond around the grit is removed. Depending on how deep the grit is embedded in the bond, it either falls out or remains with original sharpness in the bond. The grinding wheel receives a high grain clearance for maximum cutting capability, lower grinding forces and low burning risk. You can now harness the capabilities of metal bond with WireDress®. Using a bond with a high dimensional stability, almost any profile can be precision-contoured in the μm (40mill") range. Long dressing intervals can be achieved.

Yet another plus: the accurate processing of sophisticated or smallest geometries that was neither economical nor possible before, now becomes feasible. Compared to grinding with ceramic-bonded grinding tools, significant increases in productivity in the range of at least 30 percent is realistic, with resin bonds even more is possible. With a sintered metal bonded grinding wheel, you can even go beyond the limit - you can just re-dress it in the machine again. With a conventional galvanic bonded grinding wheel you can only go over the limit once. "Maximize these limits without fear - that also makes greater profitability possible," adds Michael Klotz.

Several factors for success

"If you have the right technology, the process is peanuts. In the past, you had to feel your way, today everything is process-stable. This also has the advantage that you can calculate the costs more clearly," explains Mair. He also knows that the right technology is not just about the machine. What other factors also contribute to reproducible manufacturing in the absolute range of less than 1 mu (40mill") ? "A fully air-conditioned hall, which among other things also ensures the thermal stability of our spindle, the right tooling, state-of-the-art measuring technology, optimized cooling and, of course, highly trained and motivated staff," says Mair.

Conclusion

For Fischer AG, the investment in the S41 has paid off with WireDress® technology. The productivity could even be increased by 70% for certain materials. Mair states further: "I am convinced that if this technology gets around in the professional circles, STUDER will be flooded with orders." Another advantage that should be of interest to engineers and design engineers in particular: not only can straight forms be dressed, but also very fine profiles, which was previously not possible with metal-bonded grinding wheels. This opens completely new design possibilities for engineers, and even unimaginable horizons.

FISCHER AG

Founded in 1939, the family-owned company is the world leader in engineering, development, manufacturing, distribution and service of high speed Spindle/Bearing systems. The core competence of the spindle business, the fast, accurate and powerful rotation, was consequently introduced to various technological markets and applications. FISCHER AG has around 440 employees worldwide, 260 of them in Herzogenbuchsee. The production is characterized by a high degree of in-house production. Around 180 specialists are occupied with the production and assembly of high-precision spindles. FISCHER AG has all the relevant machining and manufacturing technologies in-house as well as state-of-the-art measuring technology to ensure the performance and quality of the spindles. www.fischerspindle.ch