Multifunctional CNC Grinding Machines Optimize Production

Multifunctional CNC grinding machines help increase added value per operation—even when using carbides and other hard materials. In today’s blog, we explain which functions are involved and how you can benefit from them.

By way of introduction, here are a few examples of the functions commonly found in the latest CNC grinding machines:

- Universal cylindrical grinding machines have multiple spindles and measuring systems that enable several operations in one clamping.

- Surface and profile grinding machines can mill, drill, grind, deburr, and measure in the same clamping.

- Eroding machines can alternately erode and grind in a single operation, known as two-in-one, reducing cycle times while producing fine surfaces for carbide or PCD tools.

Measurement and Correction in the Same Operation Improve Quality

The combination of machining and measurement has significantly optimized production and improved quality control. Parts can be produced repeatedly with the desired accuracies and surface finishes while reducing measurement time.

With the extended measuring functions, you can machine a part, check the part quality with a measuring probe in the same clamping, and, if necessary, optimize the program during operation. Machine extensions also support in-process measurement and automatic correction.

Additional Functionality Means More Flexibility

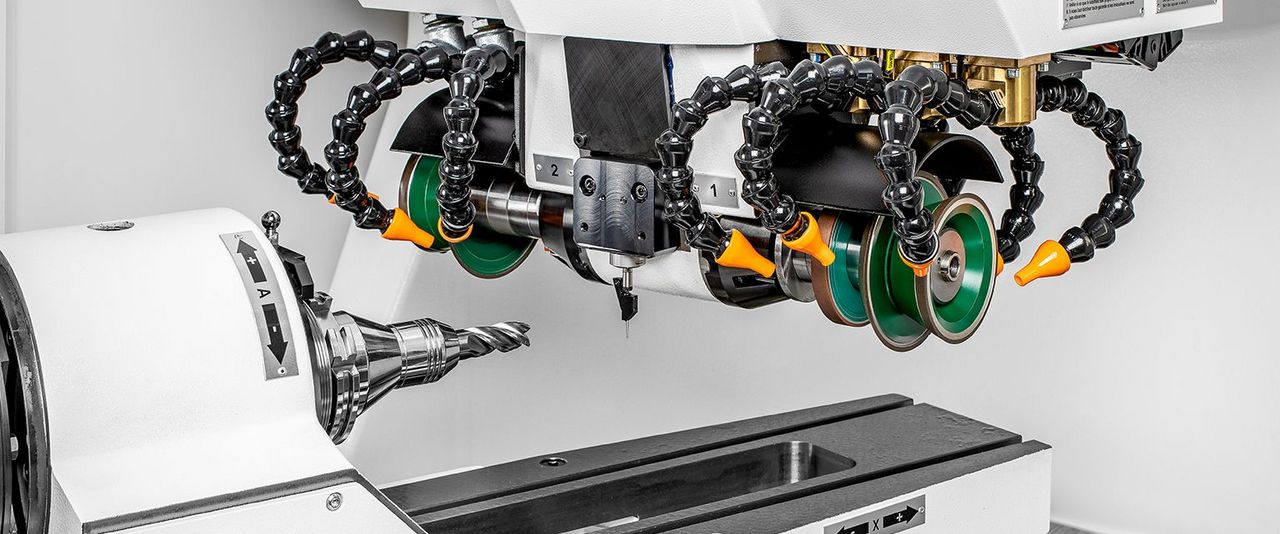

The flexibility is particularly evident in cylindrical grinding machines, which enable different operations in one clamping. These CNC grinding machines can hold up to four grinding wheels and have up to three external grinding spindles and one spindle for internal grinding. This versatility means that shoulder, taper, face, plunge, and surface grinding can be performed in the same clamping.

Advances in software, grinding wheel technology, dressing methods, and measurement allow cylindrical grinding machines to complete machining in a single operation that previously required up to five machines.

Software and HMIs Make CNC Grinding Machines Easier to Operate

Software and Human Machine Interfaces (HMIs) add functionality to CNC grinding machines in terms of programming, diagnostics, troubleshooting, and changeover.

HMIs make training new employees in programming and monitoring their machines easier and more efficient. HMIs simplify operation and monitoring and integrate with ERP systems and other software. Benefits include:

- Operators can quickly recall settings and operations.

- They can create tools from an extensive library and conduct troubleshooting via dry runs or simulations on a machine without actually grinding a part.

- Operators can program future parts while the machine is in operation.

Software plug-ins extend functionality. Options include:

- The Feedrate Optimizer can calculate the material removal rate (MRR) and reduce the cycle time by approximately 15 percent on average.

- Automatic Balancing is important for users working at high spindle speeds to ensure finish quality and spindle life.

- Sketcher allows companies that do not have the resources of a design department to design a tool with the Tool Studio software.

Automation of Machine Operation Leads to High Production Efficiency

The simplest but most effective tactic for optimizing production is to automate machine operation. This allows it to take over not just repetitive tasks, but also tasks with a certain level of risk. It brings several benefits, including covering breaks, extending production runs beyond eight hours, and lights-out manufacturing.

Some systems can connect multiple machines and workstations to integrate measurement devices, statistical process control, and wash stations. Automation makes it possible to implement other applications such as marking, deburring, measuring, and much more.

A CNC grinding machine equipped with appropriate automation performs over 90 percent of the required work per shift.

How Can You use CNC Grinding Machines to Optimize Your Production?

The additional features of today’s CNC grinding machines help you meet cycle time and tolerance specifications, budget requirements, and improved repeatability. UNITED GRINDING has a large portfolio of CNC GRINDING machines.

We would be happy to advise you. Contact us!